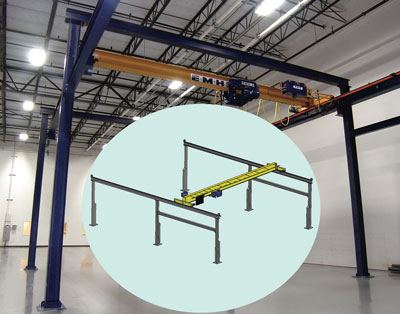

The recently introduced XW expands and extends the manufacturer’s Nomad Freestanding Crane line. The model affords overall widths and heights up to 60 feet and 25 feet, along with 2- to 20-ton capacities. The modular series provides flexible solutions for plant operators when handling needs change, or a traditional overhead crane installation is either difficult or impractical. Base plate design allows most Nomad systems to be installed without footers; with easily bolted assembly, the cranes are easily dismantled, relocated and reassembled when the need arises.

Nomad Cranes are available for one-, two-, three- or four-cell manufacturing systems, with safety-enclosed-type runway electrification brackets welded on runway beams, and conductor bars installed in the field. Each system comes complete with mounting plates, bolts and bumpers, plus top running end-truck travel speeds of 80 or 120 feet per minute (VFD). Wire rope hoists provide lifting speeds of 16/2.6 FPM with trolley speeds of 65 FPM (VFD). Bridge conductor cables are pre-wired to quick disconnect plugs.

Nomad models have radio control as standard. Each system comes complete with a hand-held AAA operated radio controller; rechargeable models are also available. A back-up pushbutton station can be provided as an option. — Engineered Material Handling, Valley City, Ohio, 330/220-8600; www.emhcranes.com