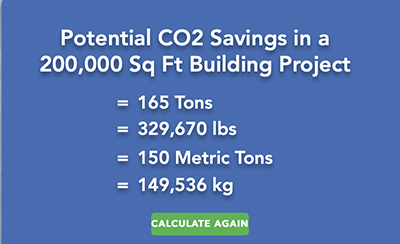

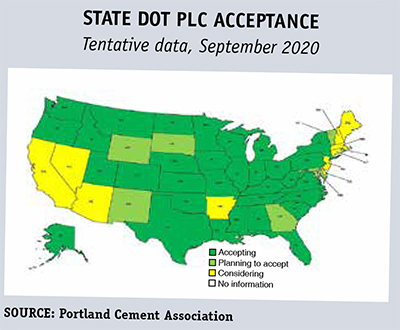

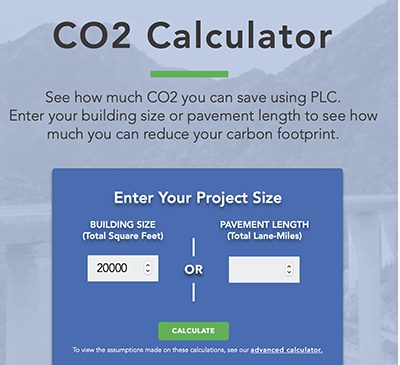

Portland Cement Association’s just-launched microsite, www.greenercement.com, supports the use of portland-limestone cement (PLC), which performs in concrete at levels comparable to Type I powder but exhibits a greenhouse gas emissions profile up to 10 percent below clinker-only material. The site accesses a calculator where design and construction professionals can input building size or pavement length to see how much PLC can reduce a project’s overall carbon footprint. In addition, greenercement.com features case studies, applications, frequently asked questions, plus the status of PLC acceptance among concrete practitioners in the United States and around the world.

“PLC is another example of the cement industry evolving, continuing to innovate and sustainably producing the high-quality cement needed to help keep America’s infrastructure strong and resilient,” says PCA CEO Mike Ireland. “This initiative will help educate engineers and other specifiers on how PLC can easily be incorporated into numerous projects.”

PLC is specified as Type IL per ASTM C595, Standard Specification for Blended Hydraulic Cements, or in Canada as Type GUL, per CSA A3000, Cementitious materials compendium.

Among departments of transportation, Type IL cements are referenced under ASTM C595 or its AASHTO M 240 companion. Type IL cement is permitted or recognized in ACI 318, Building Code Requirements for Structural Concrete; ACI 301, Specification for Structural Concrete; ASTM C94, Standard Specification for Ready Mixed Concrete; and, AIA MasterSpec.