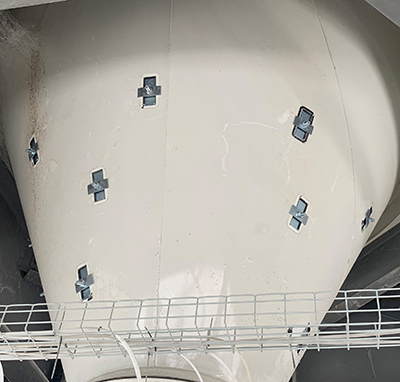

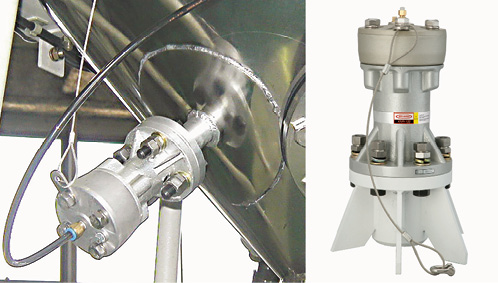

BFM connectors are designed to transform material conveying connectors from labor intensive hose clamps to snap-in fitting efficiency. In addition to providing a 100 percent leak- and dust-free connection, the BFM system eliminates hose clamped sleeves for faster cleaning and tool-free changeovers. Package includes spigots and connectors in a full range of sizes for fast replacement and fewer production interruptions.

|

|

The company’s Seeflex connectors are made from clear, long-lasting ether-based polyurethane that is memory-free and will not retain material or fracture with flexing. The design results in a tighter fit under high pressures, and the connectors have been explosion tested in excess of 60 kPa. Removal of the fitting is accomplished in minutes, and the transparency of the connector material allows visual inspection of product flow.

BFM connectors are used in thousands of conveying applications. The standardized sizes assure a tight fit every time, product engineers note, while customers realize a fast payback on the changeover to snap-in connectors through less dust and a safer environment with a product that is resistant to material handling demands. — Solimar Pneumatics, Minneapolis, 800/233-7109; www.solimarpneumatics.com