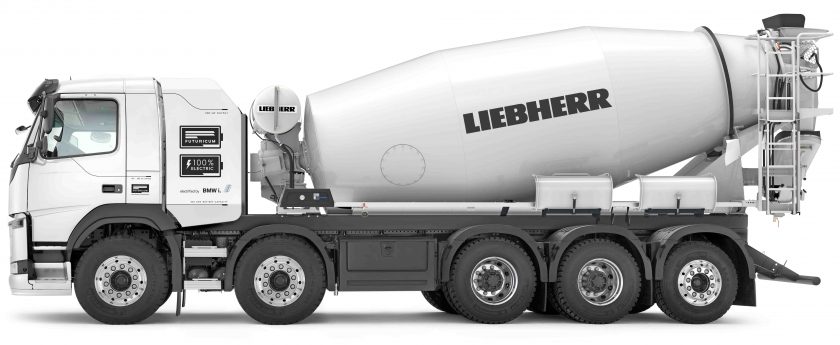

Virginia-based Liebherr USA’s parent company is set for global launch of an automated batch plant especially suiting small professional or do-it-yourself project customers. With output at about 35 yd./hour, the model is equipped for adjustable height discharge of .20- to 2.5-yd. loads in small trailers or larger vehicles, including conventional mixer trucks.

|

|

|

| The batch plant will be offered through Liebherr USA and sister subsidiaries across the globe. QR codes will simplify mix design selection and trigger the start of production cycles for up to 2.5-yd. loads. |

The self-service concrete plant affords aggregate operators or material dealers what Liebherr officials call “the ideal opportunity to offer customers an additional service and further expand their unique selling points.” QR codes enable users to select their individual concrete type and order volume, start production, then begin loading mixes in two to three minutes. The self-service model ships in two containers, transported on a single truck, and requires an operating footprint of about 1,100 sq. ft. — Liebherr-Mischtechnik GmbH, Germany, www.liebherr.com

|

| Liebherr and Heinz Transportbeton officials assemble at the manufacturer’s mixer body building flagship in Germany. |