Virginia and North Carolina precast producer Smith-Midland Corp. earned first and third place honors in the National Precast Concrete Association’s Best Practices Awards program, spotlighted last month during the Precast Show in Fort Worth, Texas. Steel Reinforcing Shop Team Leader William Garcia and Welding Shop Supervisor Ernesto Ambrosio accepted the respective first and third place awards for:

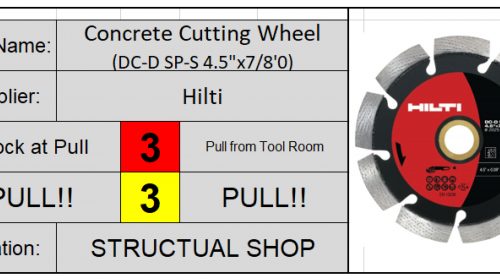

- Kanban Implementation, yielding an easily understood visual system where employees can focus on work versus inventory levels; the overall probability of running out of needed materials is reduced; and, organization, efficiency and standardization plus material delivery are addressed at set intervals. Kanban is a Japanese manufacturing system in which the supply of components, parts or materials is regulated through the use of an instruction card sent along the production line. The goal of Kanban adoption is to always have items needed for production where and when they are required. System Pull Cards are used at the point of consumption to maintain the minimum level without ever running out. When a component, part or material quantity reaches the stock at pull number, the card is placed in a mailbox near the different production areas. Cards picked up by the “water spider”—a designated team member tasked with replenishments.

- WhatsApp Lean Chat, supporting a Continuous Improvement culture critical to effective Lean Manufacturing methods. Smith-Midland created “SMC Lean Chat” on the social media platform so associates throughout its operations can share improvement ideas and techniques on their personal devices. The exchange of short videos through SMC Lean Chat upload allows team members to motivate one another to do a better job, track improvements, increase morale and foster a Continuous Improvement culture. The producer is extending the reach of the WhatsApp Lean Chat on its SmithMidlandLean Youtube channel.