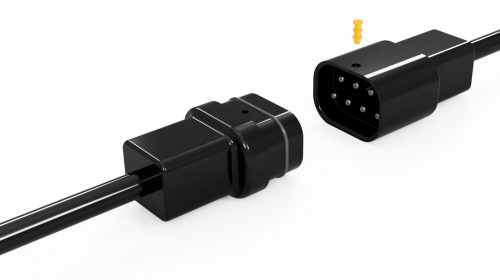

Trailer harness and electronic control system developer has secured a new patent for its Modular Connection System, superseding one for earlier and improving on the product’s O-ring-style seal and secondary lock pin design. The new version features a design variation that increases the engagement integrity between the system’s integral O-ring and the corresponding groove of its mated connection. A unique lock pin of contrasting color helps inspectors identify complete connection mating. The lock pin assures precision alignment of all components and a firm, complete, watertight union that employs dielectric grease as a sealing agent and a barrier to moisture, dirt and corrosion.

USA-PLUS Sealed Modular Wiring Harness Systems are simple to assemble and use the same Modular Connection System throughout. All of the connectors are constructed using a durable virgin vinyl molding compound. Novice assembly workers can make flawless connections quickly and repeatedly because the system’s keyed pin orientation guides a precision interface every time. Harness ends can be constructed to mate with any incandescent or LED lamp from any major manufacturer.

Salt spray exposure tests per ASTM B117 standards show that the Modular Connection System remains fully operational and unimpeded after three times the SAE testing exposure period. The assembly is offered in a variety of styles that will accommodate virtually any modular plug-together application. The USA family of connectors includes two-, four-, six- and seven-way configurations. A 10-way system has also been developed for electrical systems with auxiliary circuitry. — USA Harness Inc., Winsboro, Texas, www.usaharness.com