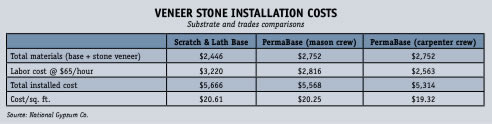

National Association of Home Builders Association-affiliated Home Innovation Research Labs finds that using PermaBase Cement Board as a substrate in exterior wall systems with modified veneer mortar reduces adhered stone installation time by 35 percent and total installed cost by 6 percent against traditional lath-and-cement mortar base alternatives.

A study comparing overall labor factors and variations between trades on the two substrate types was conducted on behalf of lead sponsor, National Gypsum in Charlotte, N.C., plus co-sponsors Eldorado Stone, Atlanta-based precast veneer producer, and Laticrete International, Bethany, Conn.-based mortar supplier. Home Innovations researchers used Group Timing Technique, a short-interval sampling procedure, to record worker activities at predetermined intervals on two identical facades of a test house, observing: a) A masonry crew installed PermaBase and adhered stone veneer in 39.4 man-hours and a scratch-and-lath system plus stone veneer in 45.0 man-hours; and, b) A carpentry crew installed veneer on PermaBase board on the same section and saved an estimated 3.5 man-hours compared to the masonry crew.

|

|

| Three different crews were used to finish 275-sq.-ft. test house sections. The initial installation entailed traditional scratch-and-lath base with Eldorado Stacked Stone veneer and polymer-modified mortar adhesive, the second National Gypsum’s PermaBase board with Eldorado Stacked Stone and Laticrete MVIS mortar. |

“Time is money and using PermaBase Cement Board as a substrate in exterior wall systems with modified mortar can reduce construction time, reduce total installed costs and increase system performance for exterior applications,” says National Gypsum PermaBase Product Manager Tony Fuller. “Given the construction industry’s shortage of skilled labor, evolving building envelope requirements and related construction costs, this is good news for architects, builders, general contractors and their clients.” Among benefits the board exhibits when measured against alternative substrates, he adds:

- Lower installed cost. Faster installation offsets material costs and expedites construction schedules.

- Lower labor cost. Requires less skilled workers and fewer labor hours per-square-foot.

- Quality and versatility. Better materials, improved system performance, cleaner jobsites, plus compatibility with multiple finishes and manufacturers.

- Compliance. Code compliant and industry approved, based on UL Evaluation Report, MVMA Installation Guide, and ASTM C1780 criteria.

National Gypsum has posted a labor, materials and building costs calculator, along with background on the Home Innovations research, at www.permabase.com/exteriors.