The most ambitious capital undertaking in the 11-year history of Lehigh Hanson Inc. entails a four-year, $600 million-plus modernization and expansion of the Lehigh Cement Co. Mitchell plant, aimed at increasing capacity from present 660,000-metric ton/year level; lowering energy usage and emissions per ton of finished cement; and, continuing to leverage the southern Indiana site’s limestone riches.

Read MoreMonth: August 2018

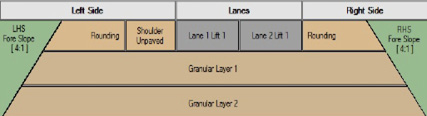

Life cycle auditor revises pavement software program

The Athena Sustainable Materials Institute, Ottawa, has updated the Pavement LCA Web App to further simplify life cycle assessment (LCA) and make paving more environmentally sustainable and cost effective. Version 3.1 features plant process data based on the National Ready Mixed Concrete Association 2016 industry average LCA and Environmental Product Declaration for concrete, plus these companion improvements:

Read MoreACI launches twin Decorative Flatwork certifications

The newest American Concrete Institute certification program offerings are Decorative Concrete Flatwork Finisher and Decorative Concrete Flatwork Associate. Each requires candidates to complete a written exam and maintain appropriate ACI Concrete Flatwork Finisher or Technician certification. Finisher candidates also need 1,500 hours of work experience. The exam covers basic knowledge of proper decorative flatwork installation and finishing procedures, addressing such topics as:

Read MoreICPI tailors paver continuing education courses to design community

The Interlocking Concrete Pavement Institute has launched three online courses covering concrete paver practice, each hosted by AEC Daily, one of the largest sources of continuing education for design professionals. Approved by AIA/CES, LA CES and other organizations for continuing education credits toward professional licensure, the courses are:

Read MoreCemex investment unit logs Concrete Sensors’ positive signal

Cemex Ventures’ first “smart concrete technology” investment is a developer of wireless sensors conveying accurate, project schedule-accelerating data. The sensor and transmitter technology of Cambridge, Mass.-based Concrete Sensors enables contractors and engineers to monitor hardening slabs’ and structures’ temperature, relative humidity and strength.

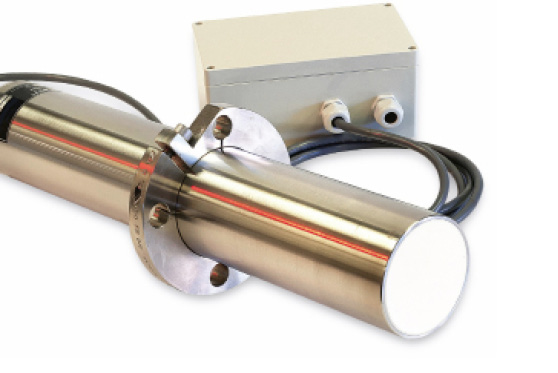

Read MoreFiber optic sensor gauges concrete curing conditions, maturity

The LumiCon system from Ontario-based Aoms Technologies enables concrete producers and their customers to remotely collect continuous, distributed, and real-time temperature and moisture data from many job sites simultaneously. It helps users control concrete curing conditions; manage the maximum internal and differential temperature in mass concrete placements; and, measure concrete maturity versus time. Real-time information delivery eliminates the need for trips to job sites to collect data or samples for testing, which improves quality, minimizes delays and reduces on-site labor cost.

Read MoreRSMeans’ construction project pricing turns on materials cost data analytics

Greenville, S.C.-based Gordian Co. has added Predictive Cost Data to its RSMeans Online service, citing the technology’s potential to deliver accurate, location-specific figures for more than 100 different types of construction projects up to three years out. With a few clicks, it delivers the cost of materials in a specific region during a particular quarter, helping users prioritize project timing and location.

Read MoreSurvey prices the leading drains on construction productivity

A survey of nearly 600 construction professionals finds that time spent on non-optimal activities—fixing mistakes, scouting data and managing conflict resolution—accounts for $177.5 billion in labor costs per year, while rework stemming from miscommunication and inaccurate or inaccessible information will cost the U.S. industry $30 billion-plus in 2018. Management consultant FMI Corp., Raleigh, N.C., and construction productivity software developer PlanGrid, San Francisco, examine how teams spend their time on construction sites, communicate during projects, and leverage technology investments. From survey responses, they determine:

Read MoreInfrastructure study findings spell gains for precast methods

Demand for precast concrete in infrastructure products is projected to increase 4.4 percent annually, to $2.4 billion by 2022, with growth fueled by the need to repair the nation’s aging network of bridges, highways, roads and railroad tracks; increased adoption of the method over traditional cast-in-place alternatives; and, efforts by the federal government to increase surface transportation investment.

Read MoreHawkeyePedershaab parent establishes umbrella identity

Iowa-based dry cast concrete machinery specialist HawkeyePedershaab Concrete Technologies Inc. has announced formation of a parent company, Afinitas. Since 2017, management notes, HawkeyePedershaab has been building out a vision of creating a global, comprehensive, customer-oriented infrastructure equipment and services platform, acquiring New Hampton Metal Fabrication Corp., New Hampton, Iowa; BFS Betonfertigteilesysteme GmbH, Blaubeuren, Germany; and, most recently, CAM Sales Inc., Ludington, Mich.

Read More