Researchers at Purdue University in West Lafayette, Ind., aim to move testing of a cellulose nanocrystal admixture from campus laboratories to a California concrete construction site this year. Derived from the world’s most common polymer, the nanocrystals strengthen concrete through a chemical reaction increasing cement particle hydration. They provide what Civil Engineering Professor Pablo Zavattieri characterizes as a rail or avenue for water to go where it is needed in the concrete matrix, especially unhydrated particles.

|

|

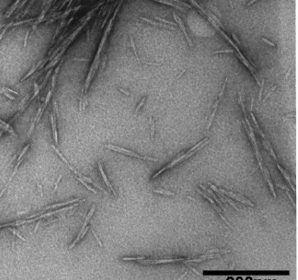

| Cellulose nanocrystals under transmission electron microscope. Derived from renewable sources, they show promise to create a new class of biomaterials for concrete and many other potential applications. MICROGRAPH: Purdue Life Sciences Microscopy Center |

“The strength of concrete scales with degree of hydration. The more hydrated it is, the stronger it is,” adds Materials Engineering Professor Jeffrey Youngblood. While water weakens concrete by adding pores, he notes, “cellulose nanocrystals enhance hydration with less water, making the concrete stronger.”

The nanocrystals are byproducts of cellulose-heavy paper, pulp, agriculture and bioenergy processes. They measure about 100 nanometers long—1/1000th the width of a typical human hair—and 5 nanometers wide, and are observed through electron microscopy.

The admixture testing and California bridge demonstration stem from a partnership between Purdue, Oregon State University and P3Nano. A public-private entity supporting cellulosic nanomaterial commercialization, P3Nano is sponsoring Oregon State demonstrations of full-scale bridge members and flat slabs cast from nanocrystal-dosed concrete mixes. The Purdue Research Foundation Office of Technology Commercialization, which operates one of the most comprehensive technology transfer programs among leading U.S. research universities, has a licensing agreement for market-grade cellulose nanocrystal admixtures with Nano-Green Biorefineries Inc.