Demonstrations of the latest Fusion Hybrid-Process Ready Mix Plant, which is equipped with four aggregate bins and features performance-boosting design changes from the original model, reveal cement-optimizing potential. CEI Enterprises credits the Fusion series’ precision aggregate blending—applied to ready mixed concrete and mimicking methods proven in asphalt pavement mix production—with a 17 percent cement savings versus standard methods. Aggregate blending, coupled with established cement and water metering, represents a hybrid process that yields a matrix with fewer voids than concrete produced through conventional aggregate batching and transfer, CEI engineers contend.

|

|

|

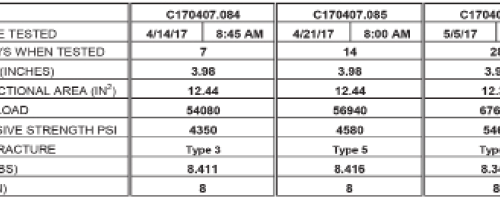

| CEI charts the strength development of a concrete mix designed with 470 lbs. of cement/yard and produced in a Fusion Hybrid-Process plant, where aggregate blending minimizes voids in finished slabs and structures. The cement factor is 17 percent below that of a mix design for a standard 4,000 psi compressive strength target concrete. |

Independent Fusion plant field tests entailed a 3-1/4-in. slump concrete produced with 470 lbs. of cement versus a standard 564-lb./yd. volume. Seven-, 14- and 28-day breaks on Fusion-derived specimens recorded compressive strengths of 4,350 psi, 4,580 psi and 5,460 psi. The finished concrete’s strength exceeded the test standard target by nearly 1,500 psi and reflected a mix with 94 fewer pounds of cement than a conventional formulation. — CEI Enterprises, Albuquerque, N.M., 800/545-4034; www.ceienterprises.com