Industrial safety specialist Castell Locks Ltd. has engineered a motion-monitoring device to protect concrete plant workers assigned mixer operating and maintenance duty. The BEMF unit ensures that motor-driven equipment up to 600V with a variable rundown time has completely stopped before access is possible. It leverages trapped key interlock technology, thus far deployed in concrete block and paver production lines to ensure power shutdown when workers enter or hover guarded machinery areas or components.

Large rotating machinery like plant mixers, Castell engineers note, present significant dangers, even when switched off, due to the momentum they build up while running. The delay between a machine being switched off and actually coming to a standstill can exceed 15 minutes, necessitating access prevention. In addition, workers gaining full-body access to rotating machinery could have a door shut behind them. The individual is then trapped inside the mixer, which could be restarted in the event of door switch activation.

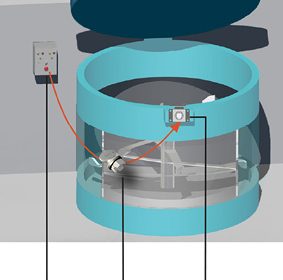

While an electric motor is rotating, whether powered or not, it generates an electromotive force (EMF), monitored by the Castell BEMF unit. When detecting zero EMF—establishing that the motor has come to a complete standstill—the BEMF unit releases a trapped key corresponding to a lock on the machine’s guard hatch. Mixer access cannot be granted without the use of the key and power cannot be restored to the motor until the key is returned once maintenance is complete.

The BEMF is also designed to improve efficiency. The time consumed by fixed-delay systems is eliminated, product engineers note, since the BEMF ensures that machine access is granted as soon as the rundown is complete. Rundown times will vary according to the load in the machine. — Castell Interlocks Inc., Chicago, 312/360-1516; www.castell.com/us