In a follow up to a November 2013 report on Active Minerals’ Acti-Gel 208, “Rheology modifer, anti-settling agent suits zero slump to SCC mixes,” Concrete Products examines the natural mineral additive’s latest application: Replacement of up to 30 percent of cement in concrete block and paver mixes, netting potential cost savings up to $0.02/unit.

Active Minerals engineers note that the Acti-Gel 208 particles, 3 nanometers in diameter, 2 microns in length, form a unique lattice microstructure that imparts a higher yield stress at rest and excellent flow properties when sheared. This allows mix designs to more efficiently stabilize both cement particles and aggregates, while enabling better forming properties and reduced deformation.

Acti-Gel 208 economizes unit masonry production by reducing cement content while increasing moisture. It augments block & paver compaction, stabilizes mixtures and improves paste quality. Active Minerals engineers have demonstrated that enabling the addition of more water benefits compressive strength development without sacrificing cycle times.

“We were recently introduced to Acti-Gel, and have been very pleased with how it performs,” says Matt Blair, vice president of Alabama-based Blair Block LLC. “Our mix designs are very unique because we try to utilize post-industrial/recycled aggregates whenever possible. Using these materials allows us to make durable and sustainable concrete products while preventing hundreds of thousands of tons from being landfilled.”

When asked how Acti-Gel 208 performs, he adds, “The Active Minerals engineer suggested three different mix designs with the same amount of Acti-Gel in each. Two of the three outperformed my baseline mix design just by adding a little extra water to the mix. Getting that extra moisture in the mix allows us to reduce our cement cost while still achieving the next day strengths and product densities we require. There is no discernible texture or swipe changes to our products, and most importantly, no slowdown in cycle times. We look forward to trying Acti-Gel in some of our other mix designs.”

Acti-Gel 208 meets or exceeds ASTM C494 Standard Specification for Chemical Admixtures for Concrete, Type S requirements. Recommended dosing rates are from 0.04 percent to 0.10 percent based on total dry weight of formula. Compatible with standard dosing equipment, the mineral additive is shipped in powder form (12- or 50-lb. bags and 0.5- or 1-metric ton super sacks) and liquid form as a slurry (1,000-liter/264-gal. IBC totes). — Active Minerals International, LLC, Sparks, Md., 800/258-2600; www.acti-gel.com, www.activeminerals.com

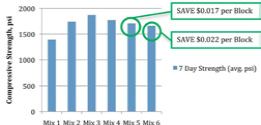

ACTI-GEL 208 PERFORMANCE

| Mix Design | Mix 1 | Mix 2 | Mix 3 | Mix 4 | Mix 5 | Mix 6 |

| Batch weight (total solids, lbs.) | 5,077 | 5,077 | 5,054 | 5,029 | 4,963 | 4,979 |

| Cement reduction | 0% | 0% | 4% | 9% | 20% | 17% |

| Moisture | 6.50% | 7.10% | 7.25% | 7.10% | 7.10% | 7.10% |

| Acti-Gel dosage (oz.) | 0 | 137 | 137 | 137 | 137 | 137 |

| Compressive Strength Mix | Mix 1 | Mix 2 | Mix 3 | Mix 4 | Mix 5 | Mix 6 |

| 7-day (average psi) | 1,390 | 1,740 | 1,870 | 1,770 | 1,705 | 1,660 |

| Savings per block ($) | 0 | -0.027 | -0.015 | -0.003 | 0.017 | 0.022 |

| One of the initial block producers testing Acti-Gel 208 observed dosage and moisture factors equating up to $0.02 per unit in cement savings. | ||||||