|

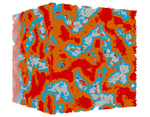

| Simulated 0.6-micron sample shows the “packing fraction” or portion of volume filled with solid materials. The average packing fraction here is 0.52. Colors indicate the variations within the sample, ranging from less than 0.4 to more than 0.64. |

To further understand concrete’s microscopic structure and behavior, researchers from the Massachusetts Institute of Technology, Georgetown University, France’s CNRS and peer institutions on both sides of the Atlantic have focused on the principal binder: Is calcium silicate hydrate a continuous solid, like metal or stone, or an aggregate of small particles? Their finding that solidified CSH is a “bit of both” could inform new approaches to lowering mix designs’ water volume and finished structures’ permeability.

“This is a quintessential step towards the provision of a seamless atom-to-structure understanding of concrete, with huge mid-term practical impact [on] material design and optimization,” affirms Christian Hellmich, director of Vienna University of Technology’s Institute for Mechanics of Materials and Structures. “[It] helps to promote concrete research as a cutting-edge scientific discipline, where the cooperation of engineers and physicists emerges as a driving force for the reunification of natural sciences across the often too-tightly set boundaries of subdisciplines.”

Concrete Sustainability Hub (CSHub) at MIT and CNRS researchers have expanded on prior modeling of concrete structure and pores at the atomic scale (particles < 10 nanometer in diameter). New work has yielded mesoscale (> 10-15 nanometer) models or simulations, and addressed some uncertainties on hardened concrete properties. According to Department of Civil and Environmental Engineering Senior Research Scientist Roland Pellenq, who serves as director of the MIT Energy Initiative-hosted MIT-CNRS lab:

- Analysis of hardened specimens’ microscopic structure shows that pores of different sizes play important roles in determining finished concrete’s characteristics.

- Solidified CSH should be considered part continuous matrix, part discrete particle assembly. Specimens’ particle distribution indicates that almost every space between grains is filled by yet smaller grains, to the point of approximating a continuous solid.

- Grains strongly interact at the mesoscale, although hardened CSH will always bear points where a smaller grain can fit in between larger grains. The binder can be seen as continuous, but the grains within it are not able to reach a state of minimum energy over length scales involving many grains. Such absence of equilibrium makes the material vulnerable to changes over time, in turn leading to creep; cracking and degradation; and, potentially, structural failure.

- New mesoscale models or simulations are the first that can adequately match the sometimes conflicting and confusing results seen in experiments measuring hardened CSH texture. They make it possible to match the values of stiffness, elasticity, and hardness in real concrete samples, and might guide research on developing improved mix designs.

MIT and CNRS modeling of hardened CSH at the mesoscale is detailed in a new Proceedings of the National Academy of Sciences paper. Joining in the research are the University of California at Los Angeles; Newcastle University, U.K.; plus, Sorbonne University and Aix-Marseille University, France. Their work is supported by the CSHub, energy services giant Schlumberger, and the French National Science Foundation.