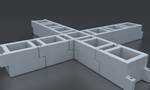

World of Concrete 2016 saw global launch of a blast-proof, crash-proof anti-terrorist barrier by United Kingdom-based RSG Structures Ltd. The modular, precast concrete KarablocK system can be quickly assembled to form a durable and effective security barrier around strategic locations, such as convention centers, airports and industrial plants. Aesthetically, a range of plant finishes can make the system suited to a range of high profile applications where appearance counts, most notably government buildings and premier hotels.

|

| KarablocK units weigh just over 7,700 lb. without ballast and can be stacked five high. |

The patented KarabloK system is made of large transportable concrete units that can be positioned either permanently or temporarily without any foundations or ground-fixing required. Units can be removed with cranes and trucks once they are no longer needed and reused elsewhere. Security fences can be mounted on top of the barrier and gates fitted within.

“The KarabloK system can be easily manufactured and sold all over the world. It provides a highly effective anti-terrorist barrier, which is quick to deploy, quick to remove and looks good too,” says RSG Structures Director Gareth Neale. “Individual units have been put through standard NATO tests and shown to provide ballistic protection from multiple strikes of 30-mm HE Cannon rounds and fragmentation protection from both medium-sized indirect fire munitions and [rocket-propelled grenade] RPG-shaped charge rounds.

“When connected together using their unique coupling system, the overall structural integrity provides effective protection against terrorist truck bomb attacks and large blasts. It has been successfully tested against the impact of 7.6-ton truck at 50 mph. The truck disintegrated, not the KarabloK wall.”

|

|

| RSG Structures has subjected KarablocK to impacts outlined in standards informing NATO blast protection and anti-terrorist strategies. A 15,000-lb. vehicle at 50 mph proved no match for the system. |

Each KarabloK is 4 ft. high and can be stacked for walls up to 20 ft. high. Units are 47 in. tall, 83 in. long, 55 in. wide and made from 7.9 in.-thick precast concrete. The block cavities are packed with ballast material to add to the structure’s 7,720-lb. weight. Two 1.26-in. jointing rebars lock units together through the KarabloK’s internal reinforcement cage. The nut, washer and bung arrangement provides the barrier with some flexibility, enabling it to withstand large blast and impact forces.

“We believe we have a world-beating product and have brought KarabloK to the premier trade show, World of Concrete,” Neale noted. “Here, we are looking for commercial partners for KarabloK at all levels, including manufacturing and sales, in North America, Australia, Europe and Eurasia where we have patents pending.” — Gareth Neale, +44 (0) 8452 997597; www.karablok.global; RSG Structures Ltd., www.rsgstructures.co.uk