The Ready Mixed Concrete Association of Ontario has officially re-branded as Concrete Ontario. Members acknowledged the group’s growth and evolution over 56 years and felt it was time for a change, noting how the new identity satisfies all of the expectations the original mark stands for while simultaneously moving the organization forward. Providing easy recall and recognition of the association, the new brand maintains a visual connection to how it was seen before.

Read MoreDay: January 29, 2016

PRODUCERS – JANUARY 2016

The board of Colombia’s Cementos Argos has unanimously appointed Juan Esteban Calle as chief executive officer, effective April. His interpersonal skills and professional record of accomplishments, directors note, will help position Argos to continue its growth and expansion strategy, while strengthening organizational culture plus good environmental and social management practices.

Read MoreSurvey finds company vision, work-life balance draw millennials to construction

An FMI Corp. report based on a national survey of nearly 400 individuals in the construction industry—half born between 1980 and 2000—contends that millennials are dedicated and loyal to their employers and, in terms of career aspirations, attitudes and goals, share similar values with Baby Boomers and Generation Xers.

Read MoreWebinar delineates RM producer, contractor responsibilities in pumping operations

In conjunction with insurance provider NBIS Inc., the American Concrete Pumping Association has produced a 55-minute webinar, posted at www.concretepumpers.com, to help ready mixed producers, concrete pumpers and contractors navigate the American Society of Mechanical Engineers “Material Placement Systems” safety standard.

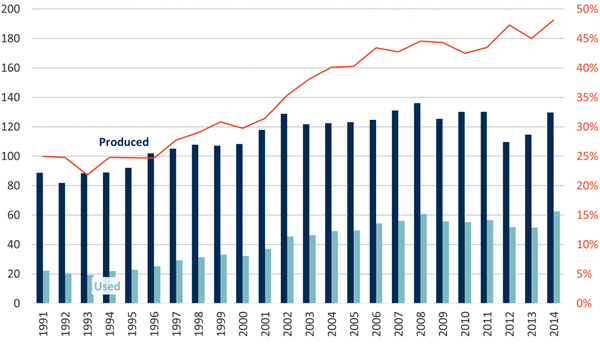

Read MorePost-EPA rule fly ash consumption eclipses pre-recession level

The volume of coal fly ash used in concrete production increased to 13.1 million tons in 2014, exceeding the 12.6 million ton utilization mark set in 2008, according to the American Coal Ash Association’s (ACAA) “Production and Use Survey,” released in late 2015. Increases in the use of synthetic gypsum from power plant emissions control equipment also helped to push the recycling rate for all types of coal combustion products (CCP) to a record 48 percent.

Read More