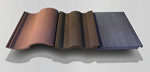

A leading independent in one of the more specialized areas of manufactured concrete, Rialto, Calif.-based Eagle Roofing Products continues regional rollout of Platinum Tile, whose patented, penetrating coating acts as a thermal insulator to reduce heat transfer into and out of a structure. Applied to freshly extruded concrete tile, the coating is a product of nanotechnology, where measurements tend to billionths of a meter.

The patented coating is composed of a material with extremely low thermal conductivity that is highly moisture repellant. Key to coating performance, product developers note, is a safe, micron-sized particle with nanoscale internal and surface modifications to the chemical architecture. The particle is incorporated into a high quality, clear, UV-resistant water-based acrylic latex, which allows it to be easily applied to multiple surface types, providing the unique combination of thermal insulation, mold/fungi resistance, moisture resistance, and UV resistance.

“Initial interest in Platinum has surpassed all of our expectations,” says Eagle Florida Regional Sales Manager Hawk Kinney. “Although all [concrete] roofing tiles offer significant savings [in] heating and cooling expense compared to other materials, Platinum may enhance those savings by 20 to 40 percent.”

“Initial interest in Platinum has surpassed all of our expectations,” says Eagle Florida Regional Sales Manager Hawk Kinney. “Although all [concrete] roofing tiles offer significant savings [in] heating and cooling expense compared to other materials, Platinum may enhance those savings by 20 to 40 percent.”

“For years our industry has strived to increase the energy efficiency of concrete roof tile through reflectivity, some would say, to the detriment of aesthetics. Platinum changes the conversation about energy efficiency forever,” adds Eagle Director of Technical Services Tyler Allwood. “Customers will enjoy the enduring beauty and protection they have come to expect from Eagle roofing tiles, paired with Platinum’s thermal insulating properties and guaranteed mold, mildew, fungus and algae resistance—without sacrificing aesthetics or strength.”

Platinum is available through Eagle Roofing sources in East and Midwest markets; a third quarter rollout is scheduled for the West. The producer secured the coating technology in a mid-2014 agreement with Industrial Nanotech, Inc., which develops and commercializes low VOC, water-based formulations.

ASTM STANDARDS ASSIST NANOTECHNOLOGY WORKFORCES

Two recently published ASTM International standards will help educators develop and refine nanotechnology course curricula at the undergraduate level, while affording businesses a basis for hiring new graduates or upgrading current employees’ knowledge and skills.

The Nanotechnology Applications and Career Knowledge (NACK) Network is helping to develop a series of standards through ASTM Committee E56 on Nanotechnology, starting with E2996, Guide for Workforce Education in Nanotechnology Health and Safety, and E3001, Practice for Workforce Education in Nanotechnology Characterization. NACK aims to help sustain economically viable nanotechnology education at community colleges and four-year institutions. Leading stakeholders are Network host Pennsylvania State University and the National Science Foundation, backing the endeavor through its Advanced Technology Education Program.

“A set of foundational standards for nanotechnology workforce education at the undergraduate level will promote uniformity in the qualifications of graduates to meet both industry and academic needs,” says ASTM member Raymond Tsui, Ph.D., a faculty associate in the Arizona State University School of Electrical, Computer and Energy Engineering, a NACK Network partner.

ASTM E2996 provides a basic educational structure in the health and safety aspects of nanotechnology, describing the minimum knowledge base needed for an individual involved in nanomanufacturing or nanomaterials research. It was developed through Subcommittee E56.03 on Environment, Health and Safety. ASTM E3001 establishes the basic structure for education in the characterization of nanoscale materials at the undergraduate level, and evolved from Subcommittee E56.02 on Physical and Chemical Characterization.

The standards are flexible enough to be tailored to regional industry needs, while retaining a high degree of equivalency in educational depth and breadth across geographical boundaries. With support from the NACK Network, Committee E56 plans to develop additional education standards, as well as an overarching standard uniting them—all falling under the jurisdiction of the newly formed Subcommittee E56.07 on Education and Workforce Development.

ASTM Committee E56 on Nanotechnology will convene November 16-17 as part of Committee Week activities in Tampa, Fla. Contacts: (E2996) Robert Ehrmann, Pennsylvania State University, State College, Pa., 814/404-0127, [email protected]; (E3001) Raymond Tsui, Ph.D., Arizona State University, Tempe, 480/206-4736, [email protected]; (staff liaison) Kathleen McClung, 610/832-9717, [email protected].