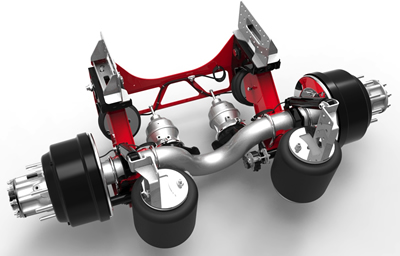

After a year of product engineering and collaboration, Iowa-based Link Manufacturing Ltd. announced at the Mid-America Trucking Show a multi-year manufacturing agreement for Volvo Trucks’ new 6×2 program. It centers on a lift axle configuration featuring Link’s robust 20K DuraMax axle with a modified 9-in. drop center. Other features include patented adjustable mounting brackets; compact frame mounting; unique air bag locations to ensure rapid axle deployment; and, open designed lift spring, greatly reducing road debris entrapment.

The system is configured within Volvo’s fuel-efficient Adaptive Loading package on its XE Series. Field-testing was conducted utilizing selected fleets ensuring multiple on-road driving applications in all weather conditions. During trials, Link-equipped 6×2 vehicles showed increased fuel efficiencies of 3–5 percent over 6×4 configurations, and extended tire life when compared to 6×2 tag configurations. Volvo will be the first truck OEM to offer the 6×2 in the pusher position for the U.S. market.

“The opportunity to partner on this project with an innovative global leader is a significant milestone,” says Link Director of Sales and Marketing Michael Hof. “Link prides itself on high-quality engineering and world-class manufacturing, but this project has challenged us to be even better. From improved efficiencies to higher environmental standards, we were able to meet the elevated expectations of Volvo.”

The Link pusher will be marketed in North America through the Volvo Trucks and Mack Trucks (see pages 36 and 45) brands. The 6×2 axle configuration will be available on the Mack Load Logic as part of the Super Econodyne powertrain package.