New Purdue University research says ‘yes’

Glow-in-the-dark concrete took the stage with new research in self-consolidating concrete, portland cement/limestone blends, and recycled concrete aggregates in ready mixed concrete, and it’s all illuminating the future of cast-in-place.

In January, 12,000-plus transportation professionals from around the world came to Washington, D.C. for the 94th annual meeting of the Transportation Research Board, and Concrete Products was there. Here’s a quick look at some of the topics at TRB of interest to readers. Next month we will examine new research in precast/prestressed concrete from the meeting.

BRIGHT FUTURE POSSIBLE FOR LIGHT-EMITTING CONCRETE

Concrete pavements can emit light and advance safety, say Purdue University’s Andrew Wiese, Taylor Washington, Dr. Bernard Tao and Dr. Jason Weiss in their 2015 TRB paper, Assessing the Performance of Glow in the Dark Concrete.

A luminescent, “glow in the dark” (GITD) sealant that could be applied to the surface of concrete has important safety benefits, in addition to creating a more durable pavement, the authors say, adding: “GITD sealant could be used to seal concrete for increased service life, to supplement streetlights, and to increase the safety of the traveling public at night. If successful, the GITD sealant could be used to improve safety in construction zones or possibly replace streetlights in certain applications.”

One such application would include nature preserves, where light pollution can be disturbing to local wildlife, but pedestrians need to see where they are walking. As GITD powder derives its luminescent qualities from sunlight, it’s more efficient than streetlights, which send light in all directions, including up, and draw approximately 2.3 percent of global electricity consumption.

Safety of roadways would be increased by using a glow in the dark sealant as drivers will be able to see the road, its edges, or critical features more clearly, Wiese, Washington, Tao and Weiss write. “Roads, pedestrian trails, construction barrier walls, bridge piers, provide just some of the other potential applications for a GITD sealant,” they say. “Using a luminescent concrete sealant, one achieves a reduction of energy consumption by reducing or replacing streetlights, placing light where it is needed, sealing the concrete for a more durable pavement, and increased safety for the public.”

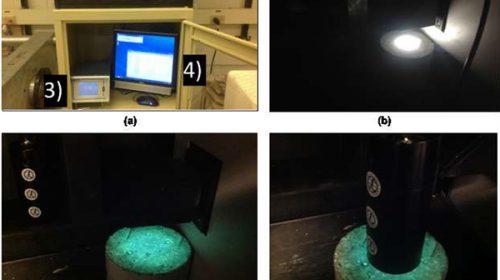

The researchers developed a soy-based luminescent sealant for use on concrete surfaces. The sealant is a mixture of soy methyl ester polystyrene (SME-PS) and strontium aluminate, a phosphorescent powder that slowly luminesces after being excited by light. A test procedure was developed to quantify the magnitude and duration of the luminance of the coated concrete surface. The luminescent sealant was excited in a consistent manner with a xenon lighting system that simulates sunlight, a photometer that measures the luminance of the excited concrete surface, and a housing unit to prevent extraneous light from the surroundings to influence test results.

“The results of the tests performed indicate that the luminescent surface emits light (i.e., glows) for approximately 24 hours in a dark space after it was excited,” report Wiese, Washington, Tao and Weiss. “It was found that larger particles of strontium aluminate luminesce for a longer time than smaller particles.”

In addition to the light emission, SME-PS increases freeze/thaw resistance by reducing the penetration of water into the concrete. “Ponding tests indicate that there is a reduction in salt ingress compared to plain samples as well,” the authors note. “Samples coated with SME-PS showed a reduction in mass absorption of approximately 50 percent for NaCl solution, 25 percent for MgCl2 solution, and 20 percent for CaCl2 solution in the absence of cracking. The ability to combine luminescence with durability enhancement could provide a sealant with multiple functionalities.”

Measuring Glow in the Dark Concrete |

|

|

| (clockwise from top left) a) Experimental setup with photometer; xenon light; flexoptometer; and, data acquisition computer. b) Xenon light exciting sample with GITD sealant. c) Sample immediately after xenon light turned off. d) Photometer capturing luminance of GITD sealant. |