Multicolor systems enable the production of concrete pavers and block with varied colors on the face side. While practice has proven that three different colors will allow for a block with natural appearance, achieving and consistently replicating the precise target composition can be challenging.

Most multicolor systems work with three silos placed parallel to the collecting conveyor that feeds the paver or block machine. A common industry approach involves using movable dosing belts located under the silos perpendicular to and dumping onto the collecting conveyor. By moving the dosing belts forward and backward the colored concrete is placed in different positions across the collecting belt to vary the placement in the machine hopper, thereby affecting the color composition in the mix. However, during the backward movement concrete will fall off in a random pattern, complicating the reproduction of the desired result.

|

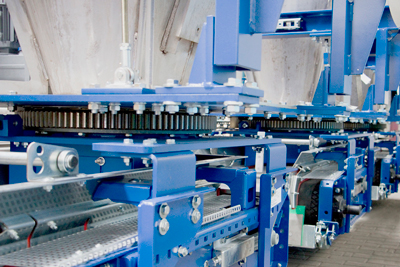

| Masa engineers place silos atop the collecting belt in a configuration aimed at improving repeatability of target color mix delivery to block and paver machines. |

Masa-USA improves on the accuracy of target color repeatability with a new alternative: Silos are placed on top of the collecting belt and dosing belts in line with it. The dosing belts pivot 30 degrees to the left and right to vary the positioning of the concrete on the collecting belt, eliminating the undesirable forward and backward movement. Additionally the new design is more user friendly, with fewer wear parts resulting in lower maintenance.

— Masa-USA LLC, Green Bay, Wis., 800/284-5507; www.masa-usa.com