A leader in bringing building information modeling (BIM) software and online tools to the architectural, engineering and construction markets, Tekla Inc. has included in its latest version of 3D modeling software, Tekla Structures 19, a new graphic feature to help contractors and ready mixed producers plan concrete orders in optimal delivery sequences.

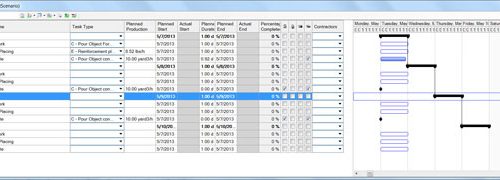

The program’s Task Manager charts formwork, rebar and concrete placement timelines by floor or other designated portion of a structure.

The Pour function allows contractors to detail all vertical and horizontal concrete conditions on a structure. It can color code slabs, connections and columns, for example, to show the distribution of all mix designs on a concrete schedule. It is among features with which Tekla Structures 19 further equips users to be more successful, productive and collaborative.

The software enables the creation and management of accurately detailed, highly constructible 3D structural models, regardless of material or structural complexity. Tekla models can be used to ensure success across the entire building process from conceptual design to fabrication, erection and construction management. While Tekla Structures 19 benefits many types of building experts, system developers contend, concrete contractors, rebar fabricators and mix suppliers will be better prepared to secure bids and improve the planning, accuracy and overall management and collaboration of project pours.

“Our goal is to help revolutionize the building industry by providing the latest advances in 3D modeling software and online collaboration tools for dramatically improved outcomes,” says Tekla Inc. President Hans Ehrnrooth. “Tekla Structures 19 moves us further toward this goal. It enables and automates the creation, planning, and estimation of detailed building designs as well as superior management and execution during the building phase itself. This results in customers gaining more projects and bid wins through innovative design while minimizing errors and maximizing efficiency and productivity.”

“We deliver an innovative software solution to the concrete industry, knowing customers remain competitive by finishing jobs faster, with less labor and waste,” adds Business Manager of Concrete Alistair Wells. “Tekla Structures 19 is written to dramatically improve accuracy, productivity, collaboration and cost savings, by initially modeling and then planning the pouring of concrete.”

PRINCIPAL PHASES

Tekla Structures 19 benefits construction users with new modeling, tracking, interoperability and management features and functionality, he adds. For concrete contractors, it offers the ability to expertly visualize and quantify concrete the way it will be placed on the construction site. This includes faster and more accurate quantity estimation, increased pour planning accuracy, and better site management and execution. The new release allows the importing of PDF drawings directly inside Tekla 3D models; its mobile access functionality makes it possible to view concrete pours on mobile tablets at the job site, resulting in faster and better decisions at critical times.

The Tekla Structures 19 model itself can be employed within various stages of construction. All project parties can benefit, from Model to Plan to Pour phases:

Model. By modeling the structure, the quick takeoff and estimate can be fast and accurate; since it is based on plans and bid documents, it is rooted in solid planning information. At this stage slabs and beams are important because mix quantities are pulled differently for individual objects.

Plan. Once the structure is modeled it can be tied to a schedule and the entire job planned in 3D. The unique element, developers note, is the ability to plan based on real pours. Automatically merging objects into continuous pours benefits concrete contractors and their ready mixed suppliers. Additionally, considering that formwork can be just as easily modeled, counted, organized and managed, the model becomes an even more powerful planning tool.

Pour. Drawings can be pulled from a model as easily as a report from accounting software. These could be lift drawings for a concrete contractor, rebar details for a fabricator or pour sequence details. All can easily contain 3D views for clarification.

Tekla officials underscore the biggest part: Taking the model and its value out into the field. Whether it is used simply to visualize issues with other contractors, manage pours or get on the spot quantities, there are numerous uses for the model in the field. Probably the most widely used is to take layout points from the model and send them to a robotic total station. Accuracy is guaranteed since the points were generated in the model and layout efficiency is enhanced with these systems.

Site Management. Tekla model continues to show benefits when it is time to pour the concrete. The software lets users manage the pours on site, and formwork team members can view their schedules and see layout in 3D.

RISK, ERROR REDUCTION

Recent Tekla Structures adopters include Wayne Brothers, a technology-savvy commercial concrete contractor specializing in negotiated private projects, where its level of service, quality and safety adds value to its client’s projects, facilities and properties. Recognizing the value of technology, the Kannapolis, N.C., contractor began looking at 3D modeling software as a way to reduce risk even further by enabling quicker response to client demands; see concrete and rebar details not visible on two-dimensional drawings; and, identify potential issues such as omission and errors in design.

Tekla Structures 19’s Pour function augments mix placement planning, and brings a visual aspect to concrete schedule mixes.

Tekla Structures 19’s Pour function augments mix placement planning, and brings a visual aspect to concrete schedule mixes.

Equipped with Tekla Structures 19, Wayne Brothers is specifically able to model its portion of a project during the preconstruction phase to identify and resolve any potential issues well before construction begins; easily import and export models and information created in other BIM and CAD applications; leverage its preconstruction model to easily develop accurate client estimates and faster sharing of the model with rebar vendor; quickly update models within a few hours of clients submitting a drawing change; and, encourage frequent model checking so design and construction officials can be confident in accuracy once a project begins.

“With Tekla, we’ve reduced the time from the award to the first rebar submittal by 50 percent, allowing us to meet the most demanding schedules,” notes Director of Technology Daniel Wayne, CM-BIM. “This gives us a clear competitive edge because we can respond quicker with more accuracy and provide a higher level of support to our clients.”

The Structures platform also facilitates close work with fabricators who use Tekla’s advanced rebar detailing capabilities to model each reinforcing member. During Wayne Brothers’ first project modeled in Tekla—a 1 million-sq.-ft. industrial complex—99 percent of the rebar was fabricated correctly.

“Wayne Brothers is a great example of a company that has not only embraced BIM for the obvious efficiency reasons, but has also made it an integral part of the way they do business and what they are able to offer clients,” says Tekla’s Alistair Wells. “Like many users, Wayne Brothers started by implementing Tekla Structures to improve process and reduce errors, but once they began using it and seeing the value, were able to further integrate it into the business and drive value in new ways.” — Tekla, Inc., 770/426-5105; www.tekla.com