Sources: Johnson Gas Appliance Co., Cedar Rapids, Iowa; CP staff Johnson Gas Appliance has completed the sale of its Curing Systems Division to St. Louis-based Afinitas, where the business will reside alongside the HawkeyePedershaab, New Hampton Metal, CAM, Amifast and Spillman brands. The deal includes CurePak curing equipment, parts and intellectual property, and comes on the heels of a major…

Read MoreTag: Concrete Curing

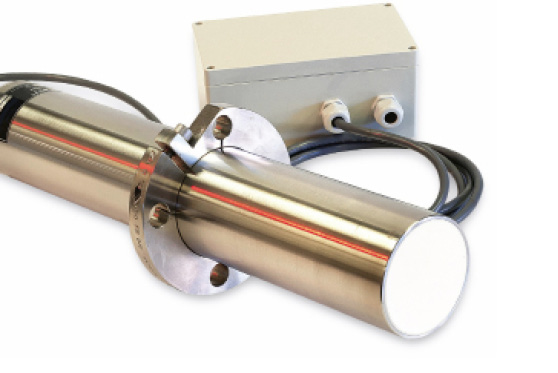

Fiber optic sensor gauges concrete curing conditions, maturity

The LumiCon system from Ontario-based Aoms Technologies enables concrete producers and their customers to remotely collect continuous, distributed, and real-time temperature and moisture data from many job sites simultaneously. It helps users control concrete curing conditions; manage the maximum internal and differential temperature in mass concrete placements; and, measure concrete maturity versus time. Real-time information delivery eliminates the need for trips to job sites to collect data or samples for testing, which improves quality, minimizes delays and reduces on-site labor cost.

Read MoreSolidia secures patent for CO2-sequestering process speeding concrete curing

The United States Patent and Trademark Office has issued a patent that will offer the global construction industry what Piscataway, N.J.-based proprietor Solidia Technologies cites is a way to reduce carbon dioxide emissions in cement milling, and provide concrete producers sustainable means to structures or slabs that are stronger, cheaper to fabricate and faster to cure than conventional portland cement alternatives.

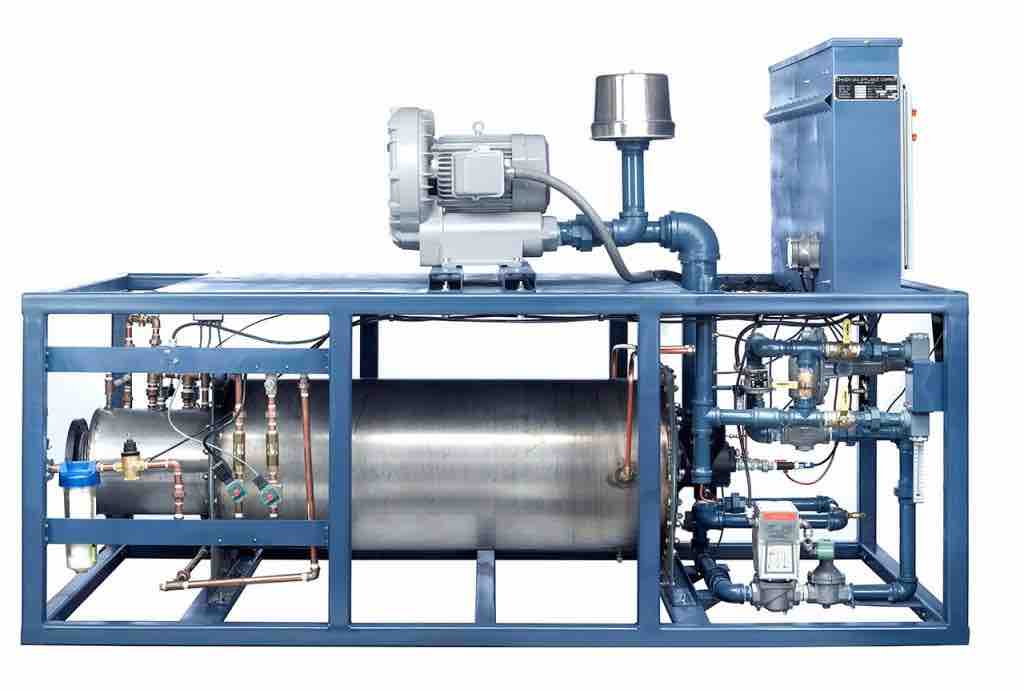

Container optimizes testing of best curing ways and means

Pathfinder Systems has added to its CureTec offerings a test container with which manufactured-concrete producers can determine the ideal conditions—notably air, steam and temperature settings, and schedules—for curing products and structures. The test container contains a steam generator, plus warm air and mist systems, which can be run individually or together. It is available for rent to test product and many different types of atmospheres and temperatures.

Read More