Vortex training simulator developer CM Labs cites release of the first concrete pump operator program of its kind. With curriculum developed in collaboration with the American Concrete Pumping Association (ACPA), it ensures operators are proficient with using the remote-control box before being exposed to work site stress. The Concrete Pump Simulator allows operators to develop basic skills such deploying outriggers, creating concrete slabs, and pouring footings or foundations. Built-in performance metrics help trainers identify areas for improvement.

“Control familiarization is extremely important in ensuring safety on the job. Mastering the remote box could take up to two months in the field but takes two weeks on the simulator,” says ACPA Past President Dennis Andrews. “Every detail from providing the superintendent with the job ticket, to operating in the rain and at night, as well as risks such as hose whipping, is replicated. Novice operators gain real-world experience faster but within a controlled and safe environment.”

Concrete Pump incorporates CM Labs’ Smart Training Technology, which means that real machine behavior from the backlash of the boom to machine hydraulics and stability are accurately simulated. “Smart Training reproduces the tension, sway and deflection felt when using a real concrete pump. The result is tailored, cost-effective training that builds transferrable operator skills,” notes CM Product Manager Julien Richer-Lanciault.

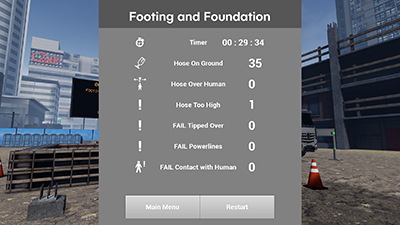

According to Andrews, the industry is headed toward formal concrete pump operator certification and the ultimate goal would be for the simulator to be used in practical testing for candidates. With built-in scoring on metrics such as time to pour, and reporting on events such as contacts between equipment and structures, Concrete Pump Simulator is geared for objective assessment of each operator’s skill sets. — CM Labs Simulations Inc., Montreal, www.cm-labs.com