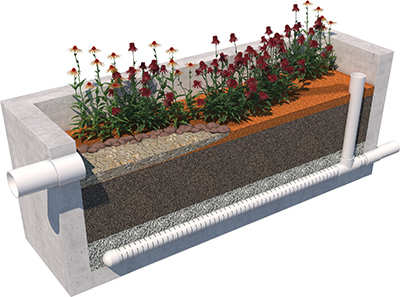

The New Jersey Corporation for Advanced Technology (NJCAT) recently tested and verified an innovative system from Nevada-based Jensen Precast as a Stormwater Manufactured Treatment Device for Green Infrastructure. The producer’s StormVault Biofiltration System with engineered Sierra Blend bio soil media is a nonmechanical, self-operating unit that will function anytime there is flow within the drainage infrastructure.

Verification of the StormVault Biofiltration System was certified by the New Jersey Department of Environmental Protection (NJDEP), capping a two-step approval process behind a nationally recognized performance validation program for stormwater devices. Twenty-eight removal efficiency testing runs were completed in accordance with NJDEP protocol. Thirteen were conducted during mass loading, 15 during removal efficiency testing. The target flow rate and influent sediment concentration were 32 gpm and 200 mg/L (increased to 400 mg/L after Run 15), respectively. The cumulative mass removal efficiency exceeded 90 percent after the first run. The total influent mass loaded through Run 28 was 193.4 lbs. and the total mass captured by the StormVault Biofiltration System was 176.7 lbs. The cumulative mass removal efficiency for the 28 runs was 91.3 percent—equivalent to a sediment mass loading capacity of 11.0 lbs./ft.2 of filter surface area.

“Based on my review, evaluation, and assessment of the testing conducted on the Jensen Stormwater System StormVault Biofiltration under the direct supervision of Professor Keith Dennett, PhD, and Professor Mark Hausner, PhD, the test protocol requirements contained in the NJDEP Laboratory Protocol to Assess Total Suspended Solids Removal by a Filtration Manufactured Treatment Device were met or exceeded,” affirms NJCAT Executive Director Richard S. Magee, ScD, PE.

“StormVault Biofiltration efficiently removes total suspended solids, metals, nutrients, oil, and grease from stormwater runoff to meet water quality standards,” says Jensen Precast Stormwater Systems Manager Walter Stein, P.E. “Deployed with the specially engineered Sierra Blend bio soil media, the system can treat higher flows than conventional bioretention units, allowing for a smaller footprint and lower overall costs.”

NJCAT test results underscored the precast concrete system’s capacity, he adds: “At 191 inches per hour per square foot, our Sierra Blend bio soil media offers the highest infiltration rate currently available. For engineers, contractors, and developers seeking a higher infiltration rate, smaller footprint, and low impact development best management practice, our new biofiltration system is the best for sustainable green infrastructure.”

Jensen Precast is one of the largest independently owned precast concrete operators in the United States, with branches in Arizona, California, Hawaii, Nevada, and Oregon. StormVault Biofiltration System approval paves the way for the producer to offer municipal and commercial customers another high-performing stormwater treatment option alongside the popular Jensen Deflective Separator and StormVault Detention Reservoir.