An inside look at the state of ready-mix concrete from producers who are prevailing against unprecedented operating challenges

It seems impossible to talk about where we are today without recognizing the disruption caused by Covid-19. Its impact on our economy will be wide reaching and hard to predict. Within this landscape, many construction materials producers are re-evaluating their use of technology to maintain efficiency and productivity while keeping workers safely distanced.

Concrete Supply’s Henry Batten |

Geiger RM’s Todd Geiger |

Geneva Rock’s Terrence Savage |

Miles S&G’s Mike Schuh |

In a roundtable discussion, these leading producers from across the country describe the pandemic’s impact on operations and their local markets, and share strategies they are using to meet today’s challenges: Henry Batten, CEO, Concrete Supply Co., Charlotte, N.C.; Todd Geiger, President/CEO, Geiger Ready-Mix Co. Inc., Kansas City, Kan.; Terrence Savage, Vice President, Concrete, Geneva Rock Products (The Clyde Companies), Murray, Utah; and, Mike Schuh, COO, Miles Sand & Gravel Co., Puyallup, Wash.

|

| The concrete construction market has remained strong in and around the bi-state Kansas City metro area. During the pandemic, Geiger Ready-Mix of Kansas City, Kan., introduced paperless ticketing to maintain social distancing between drivers delivering concrete and the contractors receiving it. |

|

| PHOTO: Geiger Ready-Mix Co. |

|

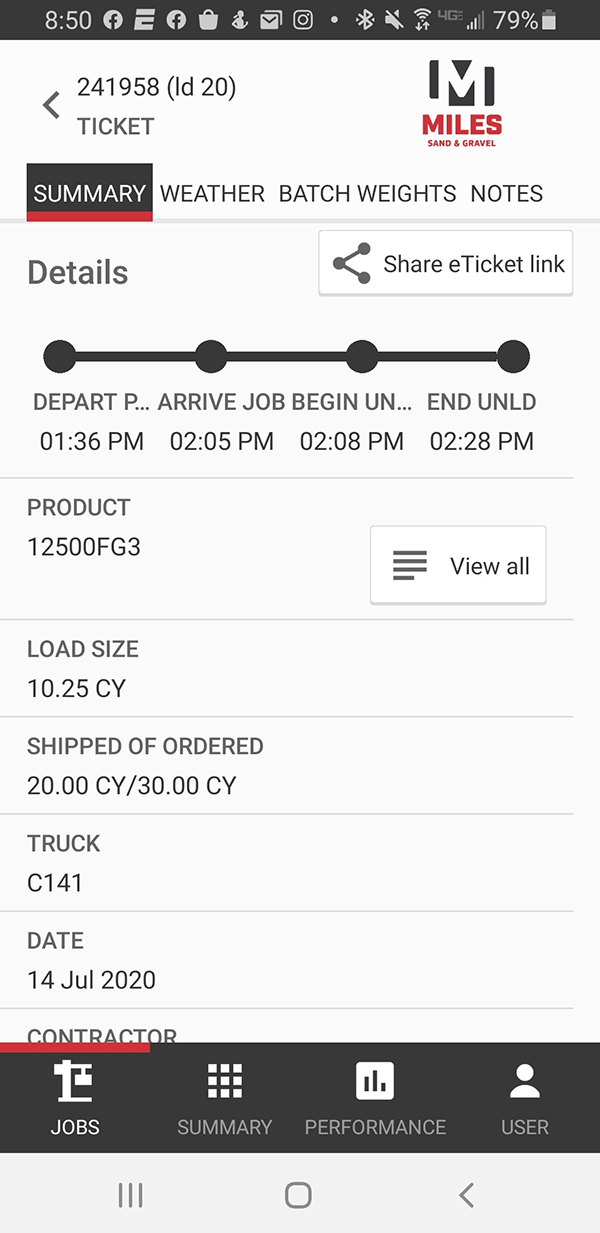

| Miles Sand & Gravel equipped delivery professionals with ample personal protective gear plus touchless ticketing capability to help them maintain distance from others while on job sites. BCMI’s Material Now supports the producer’s eTicket offering. |

|

| PHOTOS, SCREEN CAPTURE: Miles Sand & Gravel |

|

| In North Carolina, Concrete Supply’s leadership team began developing a plan for wearing masks and socially distanced team members in early March, before states and cities announced stay-at-home mandates. PHOTO: Concrete Supply Co. |

|

| In the Rocky Mountain region, Utah has seen robust construction activity thanks in part to a housing boom driven by people relocating from metropolitan areas on lockdown to less populated areas. Shown above is Geneva Rock Products, based in Murray, Utah, delivering concrete for a HUD apartment project. PHOTO: Geneva Rock Products |

|

| The Pacific Northwest’s economy has been hard hit by Covid-19-related shutdowns, resulting in many people out of work. On a Friday in May, Miles Sand & Gravel Company of Puyallup, Wash., redirected a few company trucks that normally transport aggregates to instead haul potatoes to a foodbank distribution center serving Washington State’s greater Puget Sound region. Shown here is one truck unloading potatoes. PHOTO: Miles Sand & Gravel Company |

The first and second quarters of 2020 turned out differently than anyone expected pre-pandemic. How has your company been affected?

Henry Batten: We are deemed an essential business in our state [North Carolina] and never had to shut down. What’s different now is how we operate. We’ve implemented social distancing and sent everybody home who can work from home. Our team began developing a plan for wearing masks in early March, when we recognized the problem but before the crisis took hold in the U.S. I was following news reports about how South Korea was recovering from the virus, opening back up after about 60 days of shutdowns but requiring everybody to wear masks—we used their example as guidance.

Todd Geiger: We have been very fortunate to have a robust construction market in our area [Kansas City metro]. The year started with a mild winter and dry spring, and there is still strong demand for ready-mix concrete.

Terrence Savage: Social distancing and masks have caused day-to-day operational adjustments including start times, customer interactions, load ticketing and mixer utilization (drivers not sharing vehicles), just to name a few. The May 19 OSHA record-keeping requirement for the Covid-19 pandemic, whereby all cases of infected employees need to be investigated to determine whether the infection was contracted at work, has added tremendous additional administrative burden to our operating process.

Mike Schuh: We planned to attend ConExpo-Con/Agg in March but ended up canceling to avoid taking unnecessary health risks due to Covid-19. Since then, it’s been interesting—and confusing—watching Washington State determine what is deemed “essential.” By the end of March, schools and businesses were closed, freeways were empty and a statewide stay-at-home order was in effect. Only those businesses and projects deemed “Essential Critical Infrastructure” were allowed to continue. A statewide Phase 1 construction plan was issued the end of April, and residential construction was added to the essential list in May. Business has picked back up, albeit at a subdued pace. Many businesses are still closed. Permitting is taking longer because some government offices are physically closed and their employees are working from home. Delayed permits means delayed projects. We’re thankful that we’ve been able to continue operations, and our employees are happy to be healthy and working!

What trends, if any, have you noticed that are impacting concrete construction in your area?

Batten: The biggest trend I see is for virtual meetings, like GoToMeeting, Zoom and Microsoft Teams. The technology was there before, but the speed at which it was adopted accelerated during stay-at-home mandates, even with our smallest customers. Our engagement strategy includes going to jobsites and having outdoor meetings as well as virtual meetings. We use Zoom because it doesn’t require an investment other than purchasing a license.

Geiger: Commercial is still driving the market, with the footprints of big-box warehouses getting bigger. Stay-at-home mandates and continuing concerns over the virus have led to increasingly more people shopping online and scheduling home deliveries, and larger regional warehouse and distribution centers are needed to accommodate increased inventory volumes and meet consumer demand.

Savage: With more people staying at home, we’ve seen a significant increase in home improvement projects and much higher activity related to concrete being poured in driveways, garages and other outdoor home projects. Also, with the combination of large metropolitan cities being locked down and historically low interest rates, we are seeing an influx of people relocating to the less densely populated Western states. This, in turn, continues to drive a housing boom and all related construction activity in our area [Utah].

Schuh: Caution and uncertainty. Owners and developers in the Northwest are playing things close to the vest, uncertain when Covid-19 will be in the rearview mirror. Funding for public projects is being re-evaluated. Workloads and backlogs have declined. Some delayed projects are just starting up again, but others have remained silent. As an example, we have a stalled tilt-up warehouse distribution center project that should have started in April.

Has the current state of the industry changed how you use or rely on data analysis?

Batten: We’re evaluating driver performance with tech tools now, as opposed to in-person conversations and performance reviews. We’ve moved much of our training out of the classroom and onto tablets, and we are digitally recording test results.

Geiger: In a business where minutes count, we have always liked to keep score. Improvements in data analysis over the years have allowed us to have so much more at our fingertips: load times, getting out of the yard, rinse-down times on jobsites, how long it takes to get back in line to load after returning to the yard. We monitor everything and keep the data in front of everyone to strive for efficiencies, such as minimizing the time we are sitting on the job before we start to unload.

Savage: Social distancing requirements and demand for paperless tickets and information have increased the need for visibility through the entire product life cycle. Our customers expect to have the ability to place orders electronically and use online tools to follow the order from dispatch all the way to the end of the mixer chute. Real-time information is no longer a nicety but a necessity.

Which processes or technologies adopted by your company during or after the Great Recession have proved to be especially beneficial in the current climate?

Batten: Clearly, mobile apps and mobile devices have allowed us connectivity with our systems, our customers and each other. Moving everything to the cloud these past 10 years—from dispatch to even our phone system—has enabled our team to work remotely as efficiently as if they were onsite or sitting in their dispatch chairs. None of our risk-analysis sessions in the past contemplated a pandemic, but it’s almost as if we’ve been preparing for this type of scenario for some time, thanks to cloud technology and mobile apps.

Savage: All tools associated with efficiency have been key to full economic recovery after the Great Recession, and they continue to be essential to daily operations. Mixer location tracking and driver efficiency tools have become the norm of operations. Mix design and supporting unit-cost material tracking are essential in driving down cost. Balancing the benefits that technology can provide with the offset of labor reduction requires continual evaluation.

Schuh: Since 2008, we’ve equipped every truck with telematics via computer tablet, giving our managers, dispatch, drivers and customers access to real-time information. We use Digital Fleet for truck tracking and BCMI (Bulk Construction Materials Initiative) mobile apps for immediate access to fleet availability, orders, tickets and historical data. BCMI’s Material Pro app has been a huge help—we use it every day!

Have you relied on technology in any new or unexpected ways this year?

Batten: We implemented some infrastructure changes, such as routers and other things that enhance security to support having more remote users. We also used the technology we already had to limit human-to-human interaction in production and delivery. This included introducing touchless ticketing with the help of our vendors, BCMI and Truckast. Our trucks are equipped with GPS and mobile devices to provide us with all the information we need about the batch and when it is delivered, so getting a signed ticket isn’t as critical for us as it was 20 years ago.

Geiger: When Covid-19 hit, we put together an impromptu in-house format for e-ticketing. We have since moved to BCMI’s e-ticketing platform and received rave reviews from our customers. We’ve also been heavily promoting our customer portal to clients so they can go online to look up tickets and invoices and pay their bills. As a result, we’ve seen an increase in credit card payments through the portal.

Savage: The pandemic has intensified our push to move toward a paperless system. Demand for quick and seamless electronic communication with dispatch and online order placement has risen considerably this year.

Schuh: We’re starting to deploy e-ticketing, and we’ve been testing improvements to fleet auto-statusing (when a truck leaves the plant, is on-job, begins/ends pour, departs job, arrives at plant, etc.).

How has e-ticketing made an immediate impact on your business? What do you expect the impact to be longer-term?

Batten: It allowed us to have uninterrupted business during a pandemic—and to keep our employees safe. I don’t want to ask my driver to stand in close proximity to another person on a jobsite and wait for a ticket to be signed. I don’t ever want to put employees in a position to get infected or injured on the job. In the long term, however, less physical interaction with customers means our work becomes more like making transactions rather than building relationships. We must continue to come up with strategies that keep people safe yet meaningfully connected.

Geiger: As more of our customers see the benefits of e-ticketing, I anticipate them embracing more opportunities to connect with us electronically down the road.

Savage: In the near term, information technology resources had to be re-allocated to meet the surging need of electronic communication and paperless documentation. Long-term, these enhancements will morph into “the way business gets done.”

Schuh: We’re using BCMI’s Material Now app to provide information instantly to our customers. They can access e-tickets on their phone or mobile device and see when the truck leaves the plant, when it arrives on jobsites and more. Plus, if our customers want to share ticket details with partners who normally don’t have immediate access, like inspectors or transportation department officials, they can include them in the e-ticketing system. I also see paperless ticketing eventually leading to paperless invoicing. I think everybody is tired of paper.

How has your supply chain been affected by the Covid-19 outbreaks across the U.S.?

Batten: There have been some minimal disruptions, but those have been isolated cases. Just like us, our suppliers have protocols in place to prevent failure to operate and to rebound quickly if a positive case is identified. Honestly, the weather has been more disruptive than Covid-19.

Schuh: Our suppliers have been great—they’re doing all they can to keep business operations normal.

Have customer needs or demands changed noticeably over the past few months? If so, how has your company responded?

Batten: We’ve seen some changes that are mostly regulatory in nature. For instance, those working on commercial projects may have municipal curfews imposed and cannot perform pours overnight. This compresses our schedule and forces us to be more focused on specific executions, as we do not have time on our side. Whenever our sales reps can, they go to project sites for pours to help mitigate any issues and service interruptions.

Geiger: Ever since we implemented e-tickets, our customers have been asking for more ways to digitally connect with us and their orders. In addition to providing a customer portal where they can see orders, tickets, invoices and pay bills, we equip them with the Material Now app, which allows them to see every production stat you can think of in real time.

Schuh: Everybody in the Northwest is cognizant and cautious with Covid-19. Our employees are Covid-19 screened when they arrive at work. Some customers require drivers to have their temperatures taken at jobsites, and in many cases, drivers are asked basic coronavirus-related questions. Many jobsites also assign wristbands or stickers indicating the person was screened that day. We understand that to progress under Covid-19, we must respect social distancing, wear masks, use the proper PPE and sanitize our hands. It’s a big change for everybody, and not just in construction. We’ll all get through this together!

What are your expectations for the remainder of 2020?

Batten: I am less concerned about the coronavirus than I was 90 days ago. One could argue that we’re seeing a second wave or that irresponsible behavior is leading to widespread transmission. Even so, I believe the medical community in the U.S. has learned from this virus over the past few months and has adopted treatments to effectively mitigate the impacts of the virus. Also, the majority of people are using preventive practices—face masks, hand washing. I’m not convinced shutting down commerce, which was necessary in the beginning, is the right approach going forward. I think the bigger issue we have is the upcoming political elections and the divisiveness of the people.

Geiger: We’re entering the second half of the year with a positive outlook, but we are going to remain very adaptable. Some of our customers saw jobs put on hold or even get pulled back—but for the most part, contractors in our area are still moving forward with their projects.

Savage: The workload through the balance of 2020 remains strong. During the first and second quarter, we experienced robust construction activity in our area. Based on discussions with our customers and government leaders, I expect 2020 will finish as a very strong year.

Schuh: We’re cautiously optimistic. In the Northwest, our busiest time of year is primarily April through October. We anticipate being busy until the rain returns in November. We hope 2021 will be Covid-19-free, but no one really knows when that will happen.

Victoria Sicaras is a freelance writer based in Countryside, Ill. She has 15 years of experience working as a writer and editor serving the construction industry.