by Craig Yeack

Congratulations, 500 customers purchased concrete from you in the last 90 days. Here’s the harsh truth: Only 50 really helped your bottom line. The others, depending on sales volume, work type, and work habits, may have actually cost you money. You owe it to your business to focus on the top 50, help a few more become better customers, and minimize your time with the rest. Here’s how.

Congratulations, 500 customers purchased concrete from you in the last 90 days. Here’s the harsh truth: Only 50 really helped your bottom line. The others, depending on sales volume, work type, and work habits, may have actually cost you money. You owe it to your business to focus on the top 50, help a few more become better customers, and minimize your time with the rest. Here’s how.

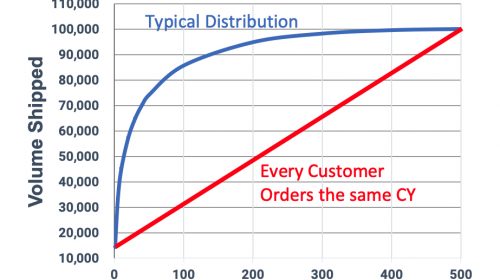

If you’re like most concrete producers, volume shipped versus customers is a fairly steep curve (see graph, below). For example, if a producer shipped 100,000 yd. over the past 90 days, about 75 percent would have gone to the top 10 percent of customers, and 97 percent of volume shipped would have gone to the top 50 percent of customers.

Producers in a “now” business like ready mixed concrete just don’t have the luxury to spend time on the bottom 50 percent of customers, which only account for 3 percent of their business. All customers matter, but for the purpose of this discussion, let’s say the top 50 percent of customers matter more, and the top 10 percent are as good as gold.

Now that we know who to focus on, what should we do? Even though a customer may order a lot of concrete, it doesn’t mean they are profitable for the producer. To understand the full picture, it’s helpful to use a customer “scorecard” (example, page 49). Let’s say you’re evaluating a fictitious contractor called ACME Construction. Based on 11 key performance indicators (KPIs), ACME has a score of 82. Notice ACME has a high cancellation rate (83 percent), which is a leading indicator for a high cost of doing business. However, overall the high volume and good rating would indicate this is a top customer. With this as a baseline, your sales team can begin crafting an appropriate quote.

FIX COMMON QUOTING MISTAKES

Raise your hand if your sales team often quotes the same amount for a given mix regardless of customer and the job’s distance from a plant. You are not alone. This “craps-shoot” approach leaves you wondering which jobs made money, or not. Considering the difficulty of conducting accurate post-job financial analysis, you might never know.

You can improve the situation by evaluating four key factors during the quoting process: variable costs, fixed costs, material costs, and finally the expense of acting as the customers’ “bank.” Each of these will help uncover assignable costs (see calculator).

Variable costs are typically where a job makes or loses money. Stories abound for orders that are switched to another plant, mix, or work type and suddenly go into the red. Start by looking at your employees’ historical performance in key areas such as loading, loaded-in-yard, and travel times. To best account for travel time, use a mapping service to show the travel time to and from the job, for each scheduled load. All of these minutes add up and have assignable costs.

Historical information about customer behavior is also essential in determining variable costs. Key indicators include average times for waiting on job and pouring given the customer’s work type performance. Average load size should also be considered in determining efficient truck utilization.

Material costs are typically similar across regional competitors and, other than mix substitution (if permissible), there is little we can do to improve. Fixed costs are, well, fixed. Long term they can be lowered by more efficient operation or higher volume throughput, but for quoting purposes they are what they are.

The cost of being your customers’ “bank” absolutely must be factored into the quotation process. Customers often pay late, dispute bills, reject loads, and lodge a host of other issues that cost the producer. Account history can be used to establish a true cost per yard of doing business with each customer. The customers you may think are your best are often not.

Now the fun begins. It’s time to create a tailored quote based on customer KPIs and known costs. There are two approaches: 1) start with the total margin over all costs, say 5 percent, and calculate the resultant price, or 2) determine the desired price and calculate the resulting total margin. Either calculation can reveal important information such as margin over material, contribution margin, and profit before tax. Some producers refine the process further by requiring minimum quoting margins by salesperson, customer and/or work type.

Real-time technology matters. With the proper tools, your sales staff can quickly review a customer’s scorecard to determine if they are in the top 10 percent to 50 percent or not, and discover areas where customer behavior could be improved to benefit both parties. Quotes can be tailored to incorporate up-to-the-minute customer behavior and plant performance to exert stronger margin discipline.

After any given order of a project ships, managers can immediately see the variance of profit margin between the quote and the actual order fulfillment and take corrective action as needed. Finally, post-job financial analysis is equally important as smart quoting. Having quick and easy access to variances such as plant changes, product changes, and delivery times is critical for making profitable decisions in real time.

| CUSTOMERS RANK QUOTING COST CALCULATOR Source: BCMI Corp. |

|

|

Craig Yeack has held leadership positions with both construction materials producers and software providers. He is co-founder of BCMI Corp. (the Bulk Construction Materials Initiative), which is dedicated to reinventing the construction materials business with modern mobile and cloud-based tools. His Tech Talk column—named best column by the Construction Media Alliance in 2018—focuses on concise, actionable ideas to improve financial performance for ready-mix producers. He can be reached at [email protected].

Craig Yeack has held leadership positions with both construction materials producers and software providers. He is co-founder of BCMI Corp. (the Bulk Construction Materials Initiative), which is dedicated to reinventing the construction materials business with modern mobile and cloud-based tools. His Tech Talk column—named best column by the Construction Media Alliance in 2018—focuses on concise, actionable ideas to improve financial performance for ready-mix producers. He can be reached at [email protected].