Enabled by the industrial Internet of Things (IoT), the Donaldson iCue subscription service monitors dust collectors and sends real-time data and maintenance alerts directly to environmental management teams. The information is designed to prompt timely response that can help improve production uptime and reduce operating costs.

|

|

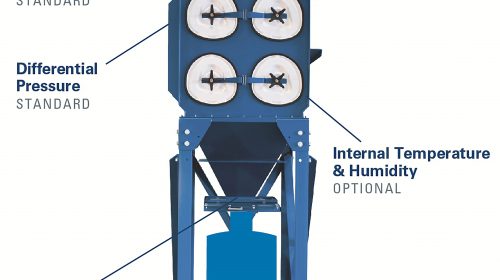

| A variety of sensor options enables users to customize the iCue connected filtration service to their application and digitally monitor critical dust collection performance data. |

Far surpassing traditional non-connected gauges, product engineers contend, the iCue service gives plant personnel access to detailed equipment performance data via an online dashboard, and sends simple, actionable notices and email reports to laptops or mobile devices. Maintenance teams can tailor information parameters to their specific applications and dust management needs. The service is compatible with major dust and fume collector brands, and a subscription includes hardware, automated reports, real-time maintenance alerts, plus online interface for more detailed analysis.

“Managers tell us that actively monitoring their dust and fume collectors’ performance is a challenge, in terms of both time and technical knowledge,” says Donaldson Director of Connected Solutions Strategy Wade Wessels. “iCue addresses this challenge by presenting real-time, actionable data through an online dashboard, alerts, and report features.”

In an independent, Donaldson-sponsored survey of plant engineers, 38 percent of respondents said a dust collector disruption would shut down their operation at an average estimated cost of $3,371 per hour. Despite the high cost of unexpected downtime, nearly half of the survey respondents said their equipment had not been thoroughly evaluated within the past three years, or the date of the most recent evaluation was unknown.

Donaldson commercialized the technology behind iCue in late 2018; between pilot and early adopter customers, facilities across a wide range of industries have benefited from the service. Initial users report results in three main categories:

- Reduced downtime for dust collection equipment and associated production lines;

- Lower maintenance costs for labor and parts, including longer filter replacement intervals; and,

- Better management of dust collector tasks and compliance reporting data.

In one recent case, iCue performance alerts reduced the time required to resolve an obstruction within a collector’s hopper from two hours to 15 minutes, through earlier detection and alerts. At another facility, filter life was extended from six weeks to approximately one year because the cause of premature filter wear was accurately diagnosed and addressed using remote access to the collector’s data.

“The iCue service connects our customers’ facilities with Donaldson, allowing the development of a new, ongoing relationship that goes beyond the initial sale of a collector,” notes Senior Director of Product Technologies Rick DeJong. “In the near future, this connection will allow us to offer additional kinds of product support, which will bring significant value as industries are increasingly struggling with gaps in maintenance labor and experience.” — Donaldson Co., Minneapolis, Minn., 833/898-5996; www.donaldson.com/connectedsolutions