New software and companion devices monitor vital components of the Vince Hagan 12-yd. Concrete Tilt Mixer.

Read MoreMonth: January 2019

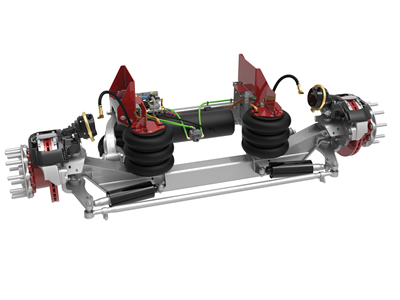

Truck suspensions equal to road, site conditions

Manufacturer engineers a variety of specialty suspensions that improve the performance, handling and safety of heavy-duty vehicles used in concrete delivery and construction. Self-steer auxiliary series feature Swift Mount technology in 8K, 10K and 13.5K capacities. The 13.5K version is available with drum or air disc brakes, the latter shown here with Bendix calipers and ConMet hub assemblies for braking performance and low maintenance operation.

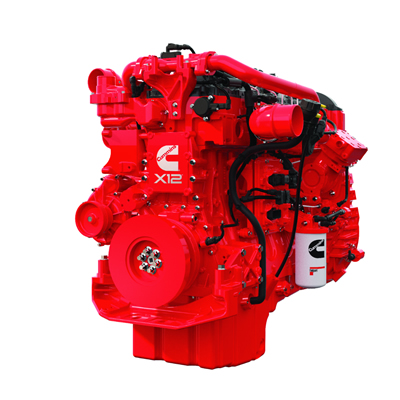

Read MoreFreightliner adds lightweight Cummins X12 engine to 114SD options

The Cummins X12 engine that entered production late last year can now be spec’d in the Freightliner 114SD. The powerful combination provides a new option for a wide variety of vocational applications, particularly in concrete mixer, dump and other trucks where weight savings are key. At 2,050 lbs., the X12 is up to 600 lbs. lighter than other medium-bore engines in the 10- to 13-liter category. Its ultra-lightweight design contributes to increased payload and productivity without compromising on the power and performance required for vocational applications.

Read MoreVolvo bundles “Payload Plus” components for bulk-ready VNR series

New packages for Volvo Trucks’ VNR regional haul series net significant weight savings, helping maximize payload and fuel efficiency in weight-sensitive tanker or bulk-haul applications. Now in production, the “Payload Plus” offering provides a simple, model-based way to shave up to 540 lbs. Packages include horizontal exhaust, aluminum wheels and lightweight chassis components; additional opportunities to reduce weight based on application entail optimized wheelbases and frame rail thicknesses.

Read MoreCon-Tech Power Chute takes hands off approach

With an eye to making concrete delivery safer and more efficient, Con-Tech Manufacturing has developed the Power Chute, which eliminates the need to physically handle and swing mixer truck extension chutes. The component was unveiled at the National Ready Mixed Concrete Association’s 2018 ConcreteWorks conference and will be prominently featured at World of Concrete 2019.

Read MoreMachines mine efficiency in underground shotcrete practice

Putzmeister Concrete Pumps GmbH is extending its range of mechanized shotcrete machines with Wetkret 4, billed as the next generation of equipment specially designed for underground construction. Wetkret 4 suits narrow galleries, thanks to its heavy-duty chassis, compact size (6-ft. wide, 7-ft. high), and reduced turning radiuses. It boasts two spraying arm versions, one with a maximum vertical reach of 33 feet, the other 26.5 feet.

Read MoreNext generation American Geothermal tanks ease operation, maintenance

Available in 5,000- to 30,000-gal. sizes, HotBatch Batchwater Tank Heaters are insulated models with integrated, high-temperature burners designed to withstand exposure in harsh ready mixed or manufactured-concrete plant environments with minimal maintenance. The tanks intuitively maintain positive features of the industry’s previous offerings while addressing their shortcomings, especially those involving maintenance requirements and insulation integrity. Among key HotBatch Batchwater Tank Heater benefits and features, product engineers note:

Read MoreConcrete placing equipment

Atlas Polar, Theam USA, Rotabelt USA

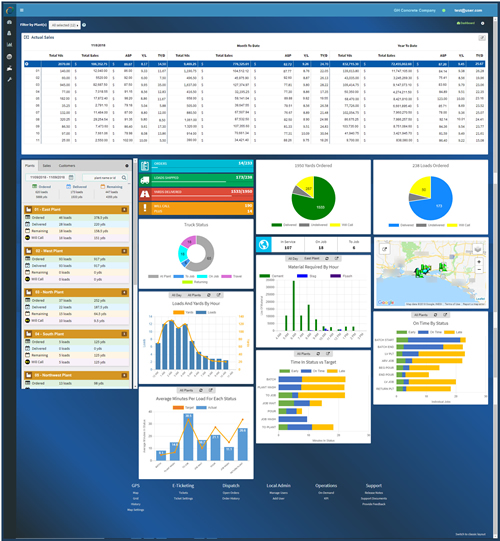

Read MoreGivenHansco maximizes production cycle control in latest online suite

Keystone Online Operations is the newest extension of GivenHansco’s advanced Keystone Online product family with which plant managers, sales teams, and owners can look at orders in ‘real-time’ to see where trucks stand. Retrieving load/batch information supports intelligent business decisions that can decrease operational costs and increase fleet efficiency.

Read MoreMass concrete specification success hinges on temperature monitoring

by Sabrina Garber

Appropriate temperatures and temperature ranges are key to maintaining mass concrete durability and longevity. The risk of temperature-related damage increases if the temperature of concrete gets too high or the temperature differential between the hottest interior point and the surface and/or edge gets too large. Therefore, many agencies include specifications that require early-age concrete temperature not exceed some maximum internal temperature limit and that temperature differentials in early-age concrete stay below some maximum limit.

Read More