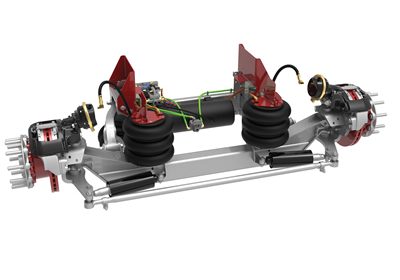

Manufacturer engineers a variety of specialty suspensions that improve the performance, handling and safety of heavy-duty vehicles used in concrete delivery and construction. Self-steer auxiliary series feature Swift Mount technology in 8K, 10K and 13.5K capacities. The 13.5K version is available with drum or air disc brakes, the latter shown here with Bendix calipers and ConMet hub assemblies for braking performance and low maintenance operation.

|

|

| 13.5K self-steer auxiliary axle with Bendix ADB22X air disc brake calipers and ConMet PreSet Plus hub assemblies. |

All of the manufacturer’s auxiliary suspensions have new rugged cast arms plus Link-KOAT migratory self-healing metal treatment for corrosion resistance and rust protection. A compact mounting envelope combined with an optional integrated air control system saves frame rail space. Separate ride height brackets and pre-plumbed integrated air control kit can save body builders and OEM three to five hours’ installation time.

The Air Link Tandem Drive heavy-duty chassis suspension combines air spring and walking beam technology to deliver high roll stability, low maintenance operation, and smooth ride. Its unique design also ensures maximum traction and load equalization when the load is full, without bone-jarring ride when empty. With dual height control valves, heavy-duty shock absorbers, and polyurethane bushings, the air ride suspension reduces operating and maintenance costs through less equipment wear, longer tire life, extended bushing life and reduced downtime compared to a rubber block alternative. Built to handle the heaviest loads, it is available in standard 46K or 52K configurations and can be retrofitted up to an 85K capacity. — Link Manufacturing, Sioux Center, Iowa, 800/222-6283; www.linkmfg.com

World of Concrete Booth C5351