The LumiCon system from Ontario-based Aoms Technologies enables concrete producers and their customers to remotely collect continuous, distributed, and real-time temperature and moisture data from many job sites simultaneously. It helps users control concrete curing conditions; manage the maximum internal and differential temperature in mass concrete placements; and, measure concrete maturity versus time. Real-time information delivery eliminates the need for trips to job sites to collect data or samples for testing, which improves quality, minimizes delays and reduces on-site labor cost.

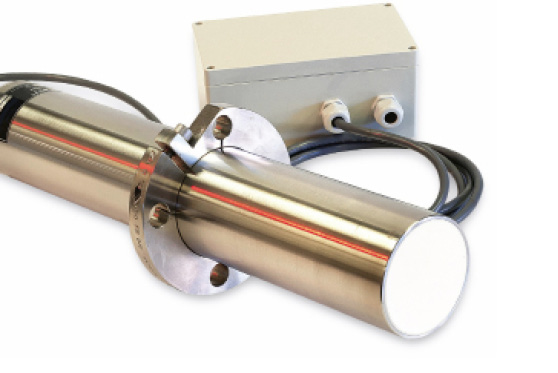

LumiCon consists of a simple, ruggedized and recoverable sensor cable that collects distributed temperature and moisture data along the length of the sensor cable to generate a 3D map of data from any concrete slab. The sensor cables can be retrieved and reused in multiple concrete projects; are easy to install without any changes in the site workflow; and, have been designed for seamless operation in cold and hot weather conditions. The system reduces the labor cost for sensor installation and data collection, and offers cloud-based data management and analytics powered by embedded LTE connectivity and a web-based dashboard.

“LumiCom has been built on innovative fiber optic sensor technology, proven for heavy-duty applications,” says Aoms Technologies President Amir Azhari. “We offer [Internet of Things] platforms to help industries collect mission-critical data to make informed decisions, streamline workflow and reduce operating and capital expenses.” — Aoms Technologies Inc., Mississauga, Ontario, 888/401-2667; www.aoms-tech.com