Five Cemex USA ready mixed plants in the San Francisco Bay Area have earned Concrete Sustainability Council (CSC) responsible sourcing certification following an audit of environmental, social, and governance practices by SGS, an independent, third-party registrar.

Read MoreDay: April 26, 2018

NRMCA chairman, committees honor annual award recipients

National Ready Mixed Concrete Association committees and divisions convening last month in Houston recognized individuals and groups for association and industry contributions. Concrete Products joins NRMCA in saluting those honored at the 2018 convention, by AWARD:

Read MorePennstress helps DOT take six-bridge schedule from months to weeks

Capturing the essence of the Federal Highway Administration’s Every Day Counts initiative, Pennsylvania Department of Transportation District 5-0 hit a grand slam by initiating, awarding and successfully completing a milestone, multiple-bridge contract designed and constructed with precast concrete components. The 2017-18 project took place along Interstate 78 in Berks County; innovative construction practices, coupled with precast girders and abutment elements, reduced the schedule for each structure from several months to several weeks.

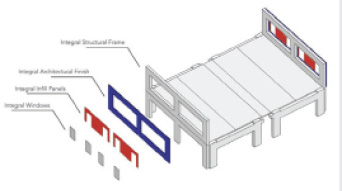

Read MoreClark Pacific programs a robust design tool for a hot market

Precast/prestressed producer and design/build specialist Clark Pacific, West Sacramento, Calif., has launched CP Campus Housing, a set of integrated structural and façade components that maximize flexibility for Type I dormitory or apartment projects, and enable more owners and designers to leverage off-site construction for cost and schedule savings plus reduced campus disruption.

Read MoreJensen Precast marks 50 years in operation

One of the largest family owned operators in underground products for commercial building and local, state or federal agency infrastructure celebrated five decades in business earlier this year.

Read MoreSuperior Walls licensee raises foundation-grade panels 15 stories

Great Lakes Superior Walls has delivered 1,600-plus precast concrete panels to enclose the 522-unit Grand Castle, a Grandville, Mich., apartment complex patterned after the architecture of a 19th-century palace in southern Germany.

Read MoreSafety reference joins ISO 9000 quality, 14000 environmental standards

ISO 45001:2018, Occupational health and safety management systems – Requirements with guidance for use specifies requirements for companies and organizations to improve occupational health and safety (OH&S) management systems’ injury-prevention performance. Developers intend for the standard to be applicable to any company or organization regardless of its size, and help reduce workplace injuries and illnesses.

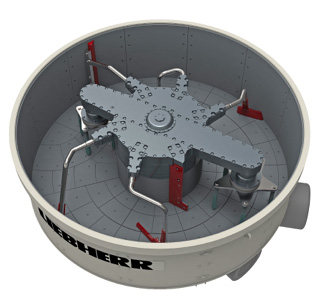

Read MoreLiebherr imparts independent shaft, agitator speed control on pan mixer

Liebherr Concrete Technology has announced North American market availability of the RIV 2.5 D Ring-Pan mixer, equipped with separate motors driving the main shaft and mixing arms plus agitator rotors. Rotational speeds of the shaft (7 to 34 rpm) and agitator (51 to 232 rpm) can be adjusted to specific concrete mix designs, and set at different rates for dry or wet loads and discharge cycles. Variable mixing control features make the model especially suited to high performance concrete.

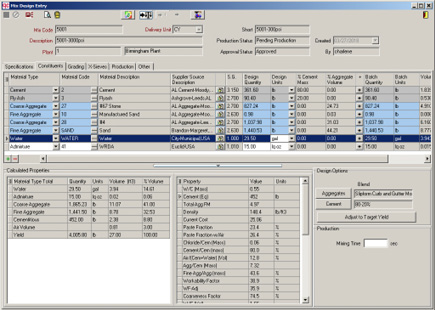

Read MoreCommand Alkon secures patent on mixing process, strength predictability

Command Alkon product design and programming veterans Bob Phare and Charlene Hohl have been awarded U.S. Patent No. 9,533,429 – System and Process for Mixing Concrete Having Desired Strength Characteristics. It covers methods for a) rapidly determining the predicted strength of concrete prior to pouring; and, b) creating and maintaining a database in which mix designs and their performance characteristics can be logged and updated as hardened concrete’s actual strength is measured. Functions based on the technology will be incorporated in future versions of the quality control platform, COMMANDqc.

Read MoreCDS elevates energy efficiency with steam-based aggregate drying method

Best known in manufactured-concrete production for its Envirocure technology, CDS has unveiled the R-O2 Drying System, whose reduced oxygen, superheated steam atmosphere serves as an energy-wise medium for bringing sand, gravel and stone moisture levels to zero.

Read More