High-performance sand and sand-based product specialist Fairmount Santrol kicked off commercialization of Accel dust-preventing polymeric sand at the 2017 Hardscape North America trade show, staged at the Kentucky Exposition Center, Louisville. Manufactured with the company’s Prevent technology, Accel reduces on-site dust and haze up to 90 percent compared with traditional polymeric sand—enhancing air quality with an engineered, environmentally cleaner formula.

Read MoreMonth: February 2018

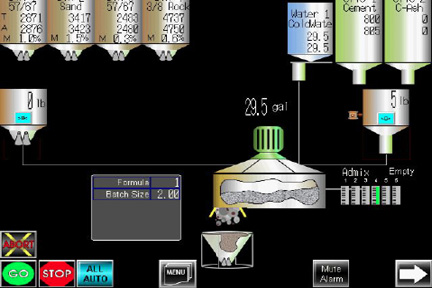

Batch panel upgrades

Programmers have added features to the BatchTron models I, II and III, giving them a new look and enhanced usability. Many pages of setup choices make all models adaptable to different concrete plant configurations without extra customization. Users can work with combinations of aggregate bins and cement silos, dry plant or with mixer, and method of aggregate transfer—by conveyor, conveyor and holding hopper, or skip hoist.

Read MoreExcavator grading technology optimizes slab, bedding material estimates

Caterpillar’s Next Generation Hydraulic Excavator series has debuted with the 20-ton 320 GC, 320 and 323 machines, each engineered to increase operating efficiency, lower fuel and maintenance costs, and improve operator comfort compared to previous models. The new models offer unique combinations of purpose-built features designed to match customers’ productivity and cost targets.

Read MoreSteam curing equipment, system engineering

The manufacturer’s signature equipment for precast, prestressed, pipe, masonry and tile curing, generates large volumes of controllable, low-cost steam. Operating at half the cost of traditional boilers, engineers note, CurePak can show return on investment in two years or less. Its capacity to produce steam instantly and initiate combustion prior to water contacting hot air equates to nearly 100 percent thermal efficiency and carbon monoxide risk reduction. CurePak also fits precast operations with flexible curing parameters, especially those requiring both intermittent and continuous steam flows.

Read MoreGalvanized rebar

Company presents GalvaBar as continuously galvanized rebar with proven protection and high formability. It can be fabricated after the galvanizing process without cracking, peeling or flaking. The process coats the steel with minimal exposure time to the molten zinc before cooling. That allows all grades of reinforcement, normal- to high-strength, to be galvanized with no risk of embrittlement.

Read MoreSpeedy masonry saw integrates dust collection

Manufacturer presents the iQMS362 as durable, portable and built to tackle any jobsite. It is equipped with the model-specific 16.5-in. Q-Drive blade, capable of 5.5-in. deep cuts at full 24-in. lengths, and equal to masonry materials in a wide range of shapes, sizes, weights and densities—from soft, manufactured stone to granite or high strength pavers.

Read MoreStainless steel rebar

High performance reinforcement is used to control the damaging effects of corrosive environments due to chlorides from deicing compounds, marine spray or contamination and spillage from chemical processing in mining, petrochemical or other industrial environments. Company cites a growing trend among state, provincial and federal transportation engineers to specify stainless as it represents the most economically viable corrosion resistant reinforcing steel for chloride attack-prone concrete. Once a structure is built with stainless steel reinforcement, owners and operator stand to see a dramatic reduction in repairs over the service life cycle. Company ships fabricated rebar and reinforcing mats throughout the U.S. and Canada. — Salit Specialty Rebar, Buffalo, N.Y., 716/299-1990, www.stainlessrebar.com

Read MoreHave you resolved to manage complexity this year?

It’s a new year and businesses are taking inventory of their organizations. By analyzing the previous year’s performance, managers typically identify short and long-term solutions to ensure greater profitability in the coming year. However, many of them fail to adequately plan for the complexities that accompany rapid growth. Experiencing such growth without adequately preparing for it can cause a myriad of challenges, including inefficiency, which leads to lost productivity, lower customer satisfaction, and decreased profitability.

Read MoreExtruder paces major Spancrete machinery series expansion

Engineers at Wisconsin-based Spancrete, a leader in engineered precast hollow core machinery solutions, have embraced product variety, plant productivity and automation in one of the most ambitious equipment portfolio upgrades in the manufacturer’s history. An expanded lineup announced last month includes new extruder, plotter, multi-function machine, multiple saws and other ancillary plant components.

Read More