Research in Mississippi shows that portland cement/limestone blends (PLC) result in notable compressive strength improvements in mixtures with high Class C fly ash replacement versus conventional Type I portland cement, say Jay Shannon and Dr. Isaac L. Howard, P.E., Mississippi State University, and V. Tim Cost, P.E., F.ACI, and Wayne M. Wilson, P.E., Holcim (US) Inc., in their 2015 TRB paper, Benefits of Portland-Limestone Cement for Concrete with Rounded Gravel Aggregates and Higher Fly Ash Replacement Rates.

PLC interest has increased in recent years, especially with new specifications, which should further facilitate marketplace use and acceptance. “Various studies have been conducted to clarify PLC’s perceived benefits and to optimize properties and use protocols for performance,” the authors report. “Laboratory-based research studies [indicate] promising PLC behavior, and there has also been successful use of PLC with 50 percent SCM [supplementary cementitious material] replacement in structural concrete for a southeastern U.S. college football stadium expansion and renovation.”

Concrete mixes made with rounded gravel aggregates and a single SCM (generally fly ash) are the most common case in Mississippi, they add. “While rounded gravel aggregates are not common to all markets, they are heavily used for concrete in Mississippi as well as numerous other regions of the U.S.”

Rounded gravel aggregates sometimes pose certain concrete quality challenges that may tend to detract from strength, observe Shannon, Howard, Cost and Wilson. “Potential issues include entrained air void clustering and inherent difficulties with paste-aggregate bond,” they write. “Some studies have documented more extreme strength loss when fly ash was used in concrete mixes with rounded gravel aggregates.”

Yet data produced in previous studies by the authors have suggested that PLC may help to relieve or even reverse such strength loss trends, making a more complete study of performance associated with this set of materials of even greater interest. The authors conclude that PLC can be used to enhance the performance (e.g. strength performance) of concrete containing rounded gravel aggregates and increased Class C fly ash replacement of portland cement. “Implementation benefits would appear to be many, including increased sustainability by way of an economically competitive and well performing concrete mixture,” they write.

PLC produced higher strengths than Type I cement, dubbed “ordinary portland cement” or OPC, in essentially all mixtures with fly ash replacement, and concrete at the 40 percent replacement level notably excelled, Shannon, Howard, Cost and Wilson find. “Strengths of concrete mixtures with slag cement were higher than those with fly ash overall, though OPC vs. PLC distinctions were less apparent,” they add.

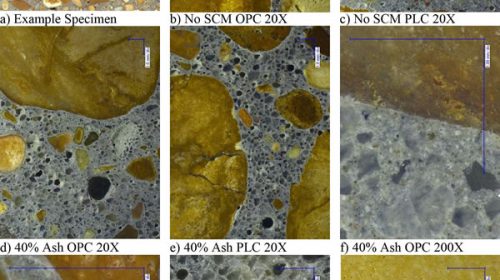

Fresh concrete properties of slump and air content were not statistically different between PLC and OPC mixtures. Time of setting was found to be lower in PLC mixtures by approximately 0.7 hour in concrete and setting indication lower by about 2.7 hours in concrete paste. Petrography revealed lighter, less uniform paste portions in OPC compared to PLC, possibly indicative of more complete cementitious hydration with PLC. The addition of fly ash appeared to lessen the differences between OPC and PLC paste appearance. OPC mixtures also appeared to have higher w/cm at the paste-aggregate interfacial transition zone.

The differences in performance trends of concrete and CP may suggest that the paste-aggregate bond is a component of some strength differences seen in mixtures with SCMs, which could be associated with particle size distribution effects influenced by significant fineness differences of the SCMs, as well as cement types (OPC vs. PLC).

|

|

| Concrete petrography was performed on four specimens (No SCM OPC [ordinary portlant cement], No SCM PLC, 40 percent fly ash OPC, and 40 percent fly ash PLC), in the interest of exploring observed strength trends thought to be possibly related to paste-aggregate bond. In the fly ash mixtures, general paste texture appeared finer with a slight chalky like appearance relative to the SCM-free mixtures. The OPC with fly ash appeared slightly coarser overall relative to the PLC fly ash mixture. |