Replacement of recycled concrete aggregate (RCA) for natural coarse aggregate by up to 45 percent by volume had no significant effects on any of the concrete properties studied, indicating high-quality RCA can be used as a replacement for a portion of the coarse natural aggregates in new portland cement concrete pavements. That’s what Haifang Wen, Ph.D., P.E., Washington State University; David I. McLean, Ph.D., P.E., Colorado State University; and, Kim Willoughby, Washington State DOT, report in their 2015 TRB paper, Evaluation of Recycled Concrete as Aggregates in New Concrete Pavements.

Read MoreDay: April 7, 2015

SELF-CONSOLIDATING CONCRETE FOR RAPID SLAB REPLACEMENTS

A refined self-consolidating concrete (SCC) mix was developed to achieve the high workability needed for faster concrete discharge and finish, and attain the Florida Department of Transportation six-hour strength requirement of 2,200 psi (15 MPa) for concrete slab replacements, report Jamshid Armaghani, Ph.D., P.E., Global Sustainable Solutions, Gainesville, Fla.; Kamal Tawfiq, Ph.D., P.E., and Steven Squillacote, FAMU-FSU College of Engineering, Tallahassee; and, Michael Bergin, P.E., State Materials Office, Florida DOT-Gainesville, in their 2015 TRB paper, Accelerating Slab Replacement Using Self-Consolidating Concrete.

FLY ASH, LIMESTONE/CEMENT BLENDS BOOST COMPRESSIVE STRENGTHS

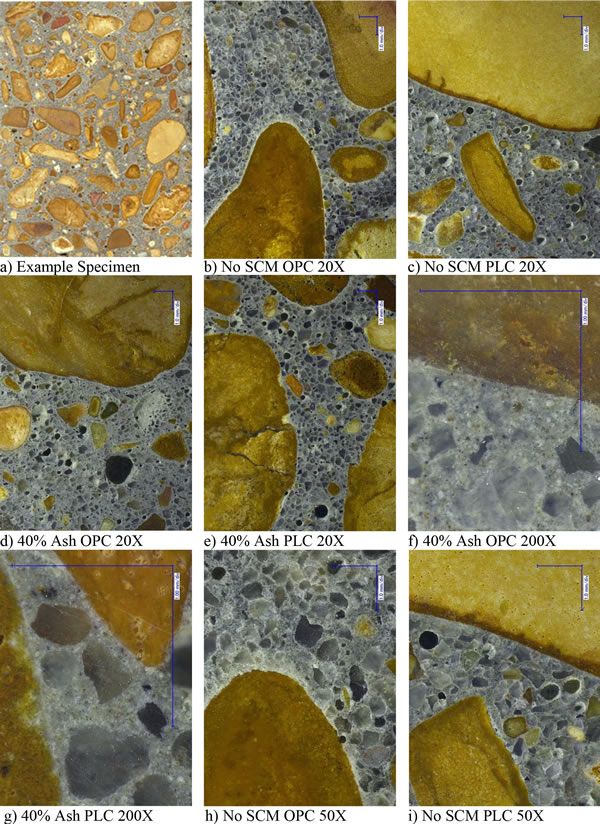

Research in Mississippi shows that portland cement/limestone blends (PLC) result in notable compressive strength improvements in mixtures with high Class C fly ash replacement versus conventional Type I portland cement, say Jay Shannon and Dr. Isaac L. Howard, P.E., Mississippi State University, and V. Tim Cost, P.E., F.ACI, and Wayne M. Wilson, P.E., Holcim (US) Inc., in their 2015 TRB paper, Benefits of Portland-Limestone Cement for Concrete with Rounded Gravel Aggregates and Higher Fly Ash Replacement Rates.

INTERGROUND LIMESTONE/CEMENT BLENDS WILL WORK IN LOUISIANA

Interground limestone/cement blends are appropriate for all uses in the Pelican State, say Tyson D. Rupnow, Ph.D, P.E., and Patrick J. Icenogle, P.E., Louisiana Transportation Research Center, Baton Rouge, in their paper, Louisiana’s Laboratory Experience with Type IL Portland Cement.

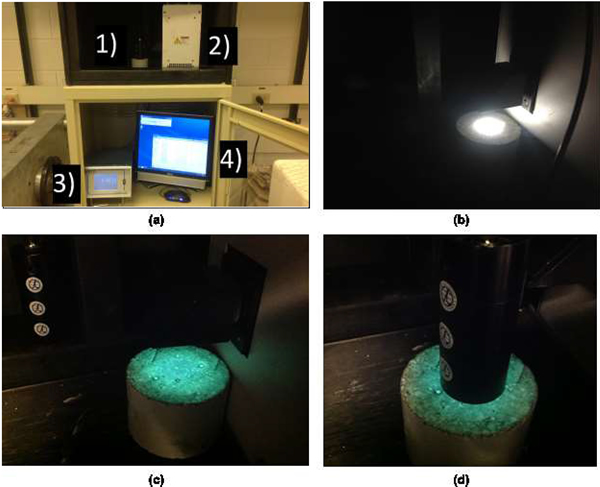

Read MoreGlow in the Dark Concrete?

New Purdue University research says ‘yes’

Glow-in-the-dark concrete took the stage with new research in self-consolidating concrete, portland cement/limestone blends, and recycled concrete aggregates in ready mixed concrete, and it’s all illuminating the future of cast-in-place.

Front Line Excellence

The National Ready Mixed Concrete Association’s 19th Annual Ready Mixed Concrete Delivery Professional Driver of the Year program recognizes two industry veterans from a pool of outstanding nominees across the country. The NRMCA Operations, Environmental and Safety Committee assembled a panel of judges to weigh nominees’ competence, driving skills, number of years without an on- or off-road accident, and colleague or customer testimonials. Judges awarded Driver of the Year honor to Eastern Concrete Materials’ Edward “Eddie” Rieper and Runner-Up honor to Concrete Supply Co.’s Henry “Pete” Scarborough. NRMCA-affiliated Truck Mixer Manufacturers Bureau will award Rieper $5,000, and Scarborough $1,000. Both drivers will be formally honored this month during the NRMCA Annual Convention in Orlando.

Porous Pave reaches recycling watermark

Through 2014, Porous Pave Inc. has manufactured product bearing about 6 million lb. of rubber recycled from 200,000 tires. An option for green stormwater infrastructure, Porous Pave is a highly porous, durable and flexible surfacing material consisting of recycled rubber, aggregate and a binder. Controlled shredding and processing of discarded tires produces the one-quarter-inch nominal size rubber chips incorporated into Porous Pave.

CDS, Solidia Technologies team on precast concrete curing chamber development

Solidia Technologies, a Piscataway, N.J., developer of proprietary cement and concrete production methods with lower carbon dioxide loads than conventional alternatives, and United Kingdom-based CDS Group, the world’s largest curing and drying specialist company, have announced a collaboration aimed at developing equipment designed to replace water with CO2 for precast concrete curing. Targeted innovations will include technological upgrades for existing curing chambers and the design and manufacture of new assemblies to accommodate Solidia’s patented CO2-curing process.

Read MoreParent company maps Grace Construction Products’ independent future

Directors have approved a plan to separate Columbia, Md.-based W.R. Grace & Co. into two independent, publicly traded companies, each with interim designations: New GCP, spanning concrete admixtures- and cement additives-anchored Grace Construction Products, and New Grace, comprised of petroleum and chemical processing-driven Catalysts and Materials Technologies.

MANUFACTURERS – March 2015

An agreement between Montreal-based McInnis Cement and Centre québécois du Droit de l’Environnement (CQDE) advances the producer’s 2 million ton per year mill and marine terminal development in eastern Quebec. It calls for CQDE to withdraw from legal action through the Quebec Environment Ministry aimed at invalidating the authorization certificate for McInnis Cement’s Port-Daniel-Gascons operation.