|

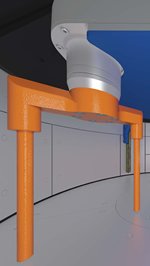

With two or four vertical bars, plus optional attachments, the whirler can be programmed at various revolution speeds and to change direction at target intervals. It works in tandem with the single- and twin-arm rotors. Two motors, coupled with a robust, precise gearbox, enable independent rotor and whirler speed control. Since different face mixes warrant different mixing action, Pemat engineers will configure the whirler to plant- and material-specific guidelines. The technology augments fast, clean discharge, and is available in on the Black Edition Multi-Mix and Pemat standard planetary and high speed pan mixer models. |

Under a new partnership, Concrete Batch Systems represents Germany’s Pemat Mixing Technologies in the U.S. and Canada. The Maryland-based plant specialist will offer a full range of components and mixer models, including series equipped with the patented “whirler” technology Pemat unveiled earlier this year:

- Hi Speed Pan Mixers, 0.25- to 4.5-yd. output (PM Standard or PMR w/whirler) or 2- to 5-yd. output (PME with reduced diameter sizes);

- PMPM “Black Edition” MultiMix Planetary Mixers, 0.4- to 0.65-yd. output for face mix and small precast operations, available in signature or standard colors;

- PMP Standard or PMPR Planetary Mixers, 0.4- to 5-yd.; PMPL with light execution gearbox, 0.33- to 0.65-yd.; PMPE with reduced diameter output, 2.5- to 4.5-yd.; and, PMPRE with whirler and reduced diameter output, 2.5- to 5-yd.;

- Conical Mixers, dry or wet, PMK1, 1- to 4.5-yd.; PMK2, 0.13- to 4-yd.;

- Zyklos Rotating Pan Mixers, Models ZZ and ZK, lab sizes through 1-yd.; and,

- Skip Hoists, sized according to mixer capacity; PAS bottom discharge, PAK roll over discharge and PAKS roll over, dust-free discharge.

The PMPM Black Edition and whirler technology will premier in North America at The Precast Show 2015, March 5-7 in Orlando. — Concrete Batch Systems, 800/256-7221 ext. 101; www.concretebatch.com; www.pemat.de